Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Ultimate Guide for Using Torque Wrench

Popularity : 1681Ultimate Guide for Using Torque Wrench

Operating Steps

-

Use other tools, such as ratchets or wrenches, to tighten the screw bolts initially.

-

Then utilize the torque wrench to screw the target till reaching the given or recommended torque value.

-

Torque wrenches are precision tools, and the goal is to assure the torque value of the suspended object. Do not use the torque wrenches as general wrenches.

Appropriate Using Form

While operating, your hand should grab tightly on the middle of the handle. It is important that wrong form can result in inaccurate torque or the damage of torque tools.

Stop Applying Force When the Torque Value is Reached

A click sound or vibration implies that the torque has reached the value you set. Please stop applying force immediately in order to prevent the screw bolt or torque tool from damaging.

Lower the Torque to the Lowest Value

In order to avoid the issue of elastic fatigue that commonly happened on the interior spring due to the long term stress, the process of setting the torque to the lowest value is highly recommended after finishing the work.

Proper Cleaning and Storage After Use

Keep the tools cleaned and stored properly is one of the method to lengthen the life time. Please remove and wipe off the impurities and splotches that contaminated the tool while working. Assure the tool is dry, then store it in the tool box or storage case.

Calibrate the Tool Regularly

Calibration must be done regularly to ensure accuracy. Suggested calibration period is at least every 12 months or 5000 times of usage.

Dismantling and Modifying are Highly NOT Recommended

Do not disassemble or remodel the torque wrench by yourselves in order to prevent the circumstances of dysfunctional and unstable from happening.

Safety is the First Priority

To avoid the situation of hurting someone or yourself accidently, please note that waving the torque wrenches is strongly forbidden! Meanwhile, dropping might the damage of interior parts and lead to the dysfunction of the torque wrench. Therefore, avoiding the tool from dropping is also a significant matter.

Link to the official website to check out the KING TONY Torque Tools~

Recommended Products

Window Type Adjustable Torque Wrench (Newton Meter & English)

34466-FG

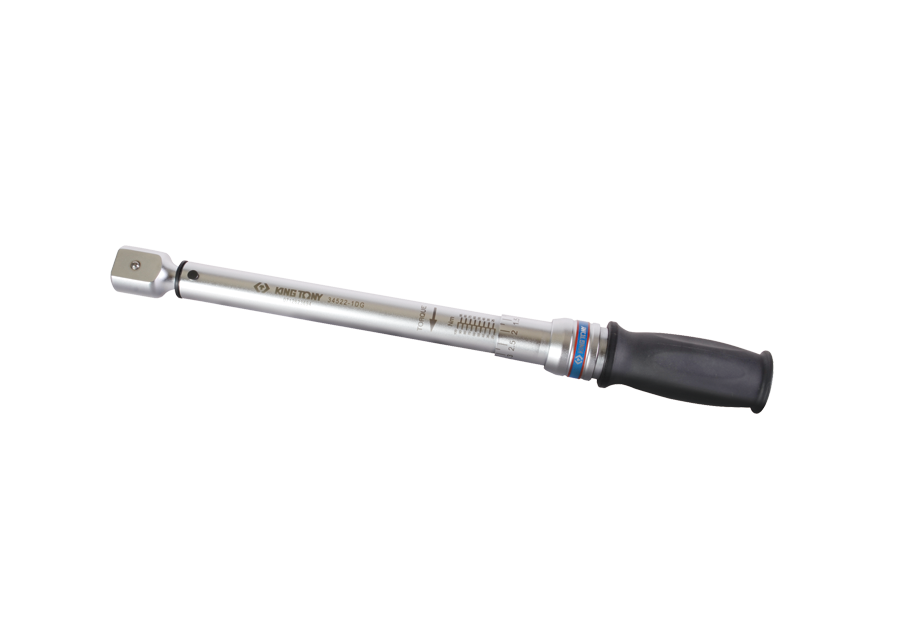

9x12 Heavy Duty Interchangeable Torque Wrench (English & Newton Meter)

34512-CG

Heavy Duty Adjustable Torque Wrench (English & Newton Meter)

34462-CG

1" DR. Heavy Duty Adjustable Torque Wrench (English & Newton Meter)

34862-2C

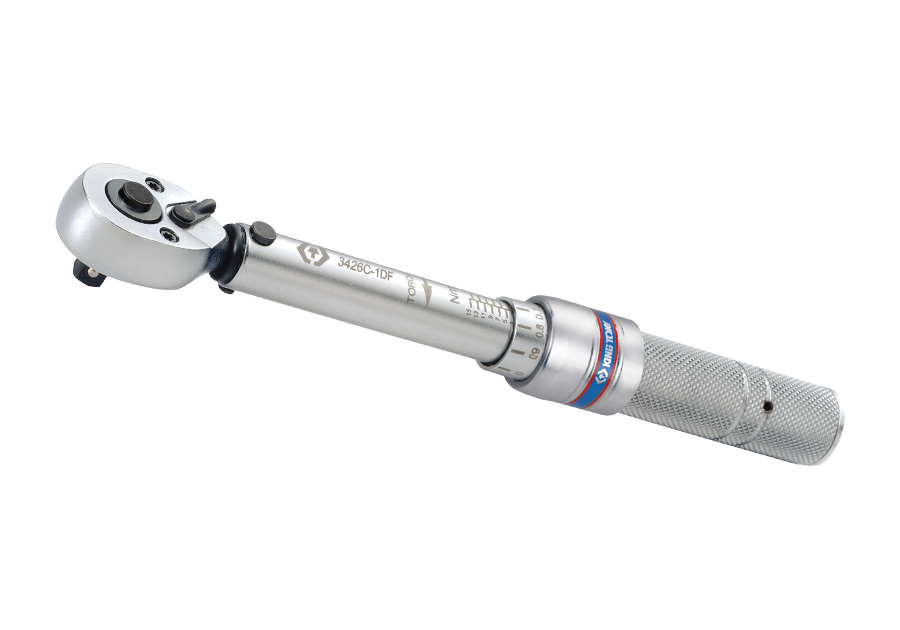

Mini-type Heavy Duty Torque Wrench (Newton Meter)

3426C-DF

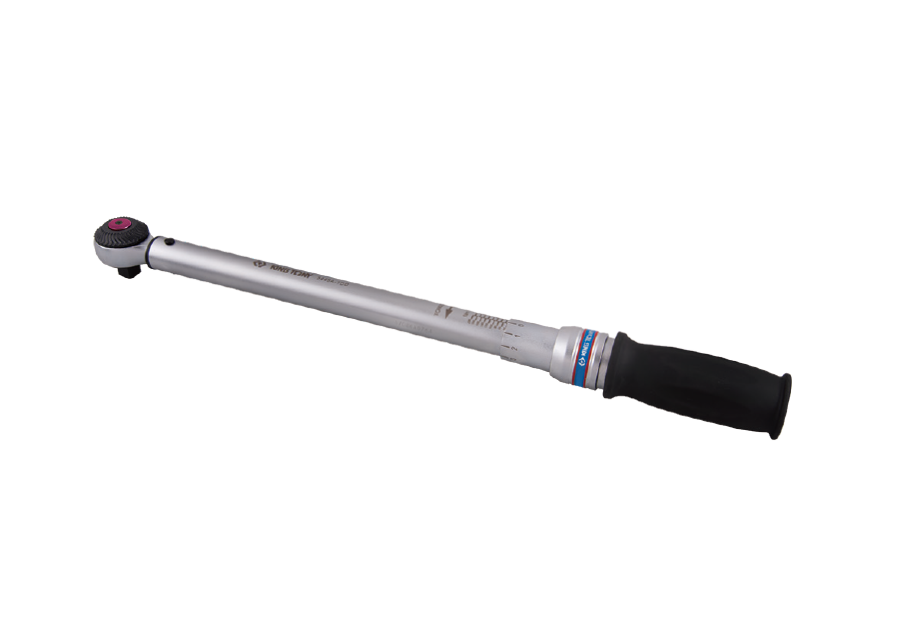

72PT Heavy Duty Adjustable Torque Wrench (Newton Meter)

3446A-DG