Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Torque Wrench Series

Popularity : 51224Styles of Torque Wrenches

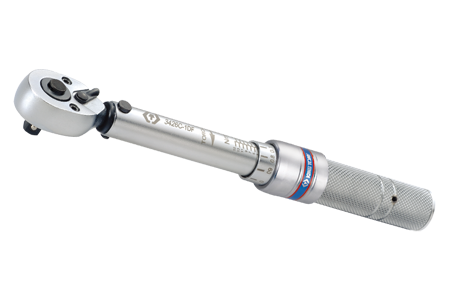

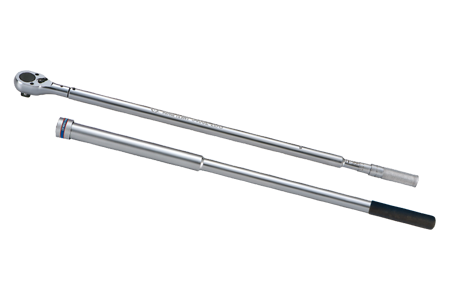

Generally speaking, torque wrenches can be divided into three styles, which are L style that includes mini type, elongated type and 72 PT. type, window style and torque screwdriver. KING TONY’s torque wrenches are separated into industrial style and professional style according to the frequency, accuracy and life time.

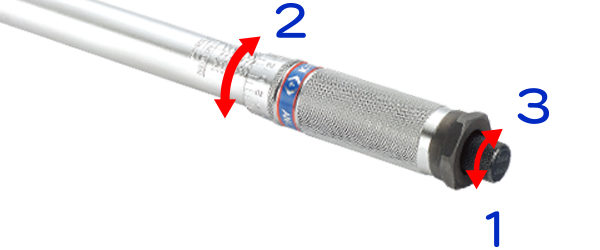

Adjusting an Industrial Torque Wrench

-

Pull: Pull down the ring that is above the handle.

-

Rotate: Rotate the grip in clockwise direction to increase the torque value. On the contrary, decrease the torque value through rotating the handle in counterclockwise direction.

-

Release: Release the ring to fix and lock.

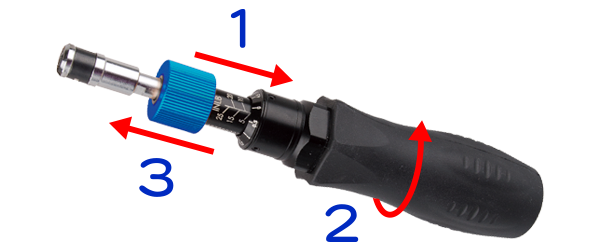

Adjusting a Professional Torque Wrench

-

Loosen: Loosen the adjusting screw.

-

Rotate: Rotate the grip in clockwise direction to increase the torque value. On the contrary, decrease the torque value through rotating the handle in counterclockwise direction.

-

Tighten: Tighten the adjusting screw.

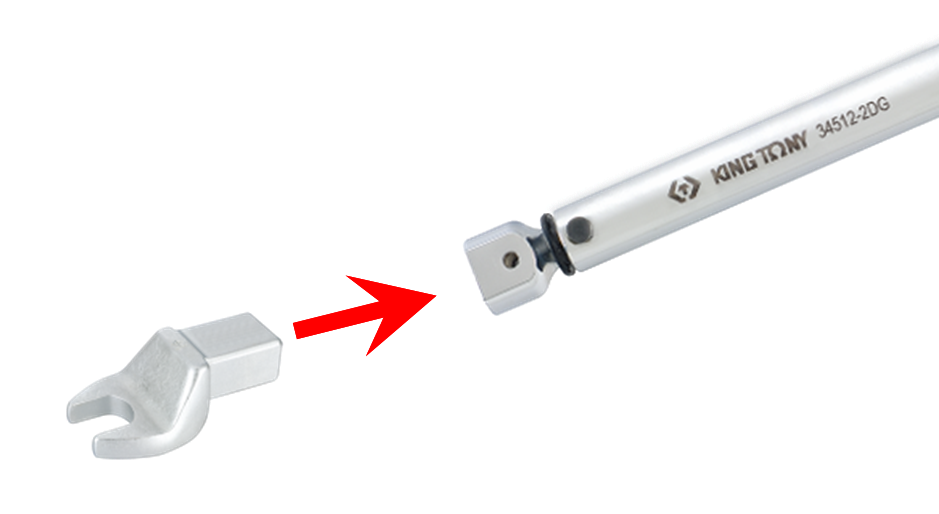

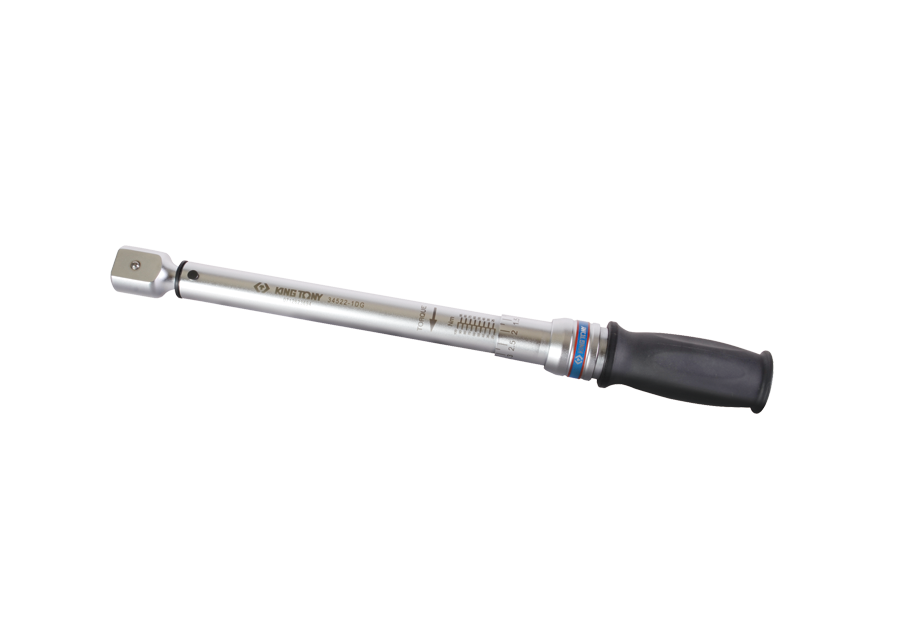

Interchangeable Torque Wrench

Torque Screwdriver

Precautions

-

After using the torque wrench, please lower the torque to the lowest value in order to prevent the issue, inaccurate torque value, that caused by elastic fatigue of the long term stressing spring, from happening.

-

Do not operate the torque wrench as a dismantle tool to avoid the parts from damaging.

-

Avoid heavy fall.

-

When abnormal situation appears while operating, inspect the parts of the head initially. If the head function normally, the matter might be caused by the dysfunctional interior structure parts, which requires contacting with the repairing crew.

-

According to the protocol, calibration is necessary after operating the torque wrench over 5000 times.

-

In order to assure the accuracy of the torque value and prevent troubles while using, dismantle no parts inside the tube.

Recommended Products

Window Type Adjustable Torque Wrench (Newton Meter & English)

34466-FG

9x12 Heavy Duty Interchangeable Torque Wrench (English & Newton Meter)

34512-CG

Heavy Duty Adjustable Torque Wrench (English & Newton Meter)

34462-CG

1" DR. Heavy Duty Adjustable Torque Wrench (English & Newton Meter)

34862-2C

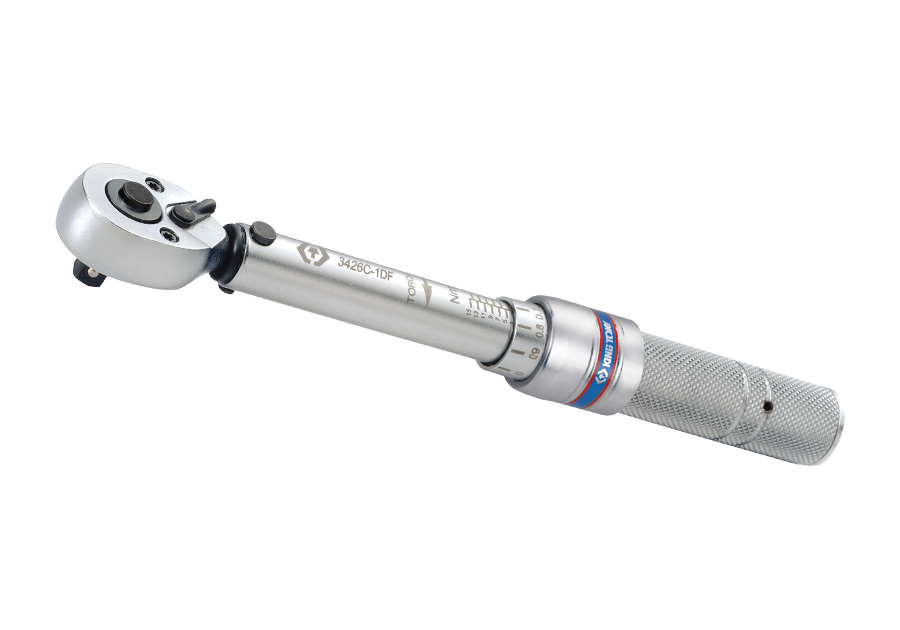

Mini-type Heavy Duty Torque Wrench (Newton Meter)

3426C-DF

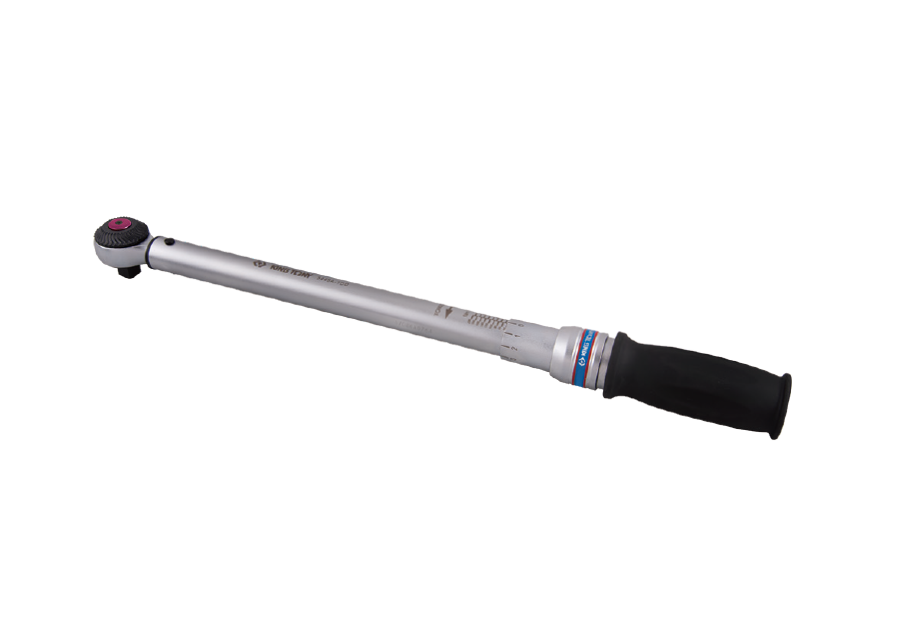

72PT Heavy Duty Adjustable Torque Wrench (Newton Meter)

3446A-DG