Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Torque Multiplier

Popularity : 86343The Purpose and Functions

-

Approach high torque value easily while working in a small space.

-

No extension bar means safer operation.

-

1:5 multiplication makes the work time saving and effort saving.

-

Maximum output torque value is 2700Nm.

Working Environments

-

Places without power source, including electricity or air compression system. For instance, heavy outdoor constructions such as railway laying or tower building.

-

Places with a narrow space that extension bars cannot be used.

-

Places that striking tools cannot be used.

Specification

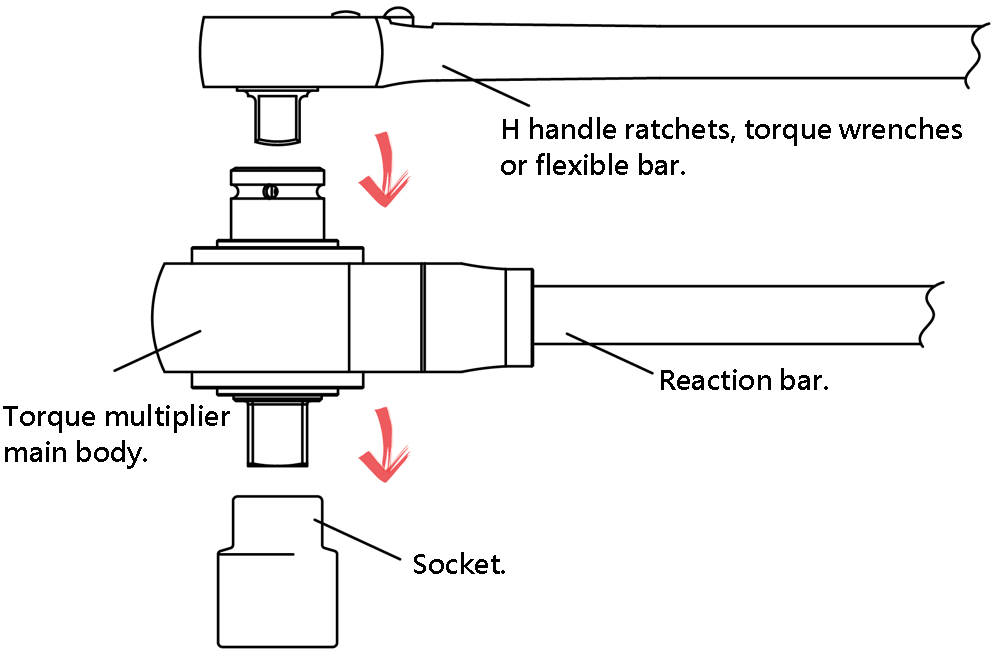

Parts of the Torque Multiplier

3/4" Input

Tapped hole / Screws for Fixing

1" Output

Straight Reaction Bar

L Type Reaction Bar

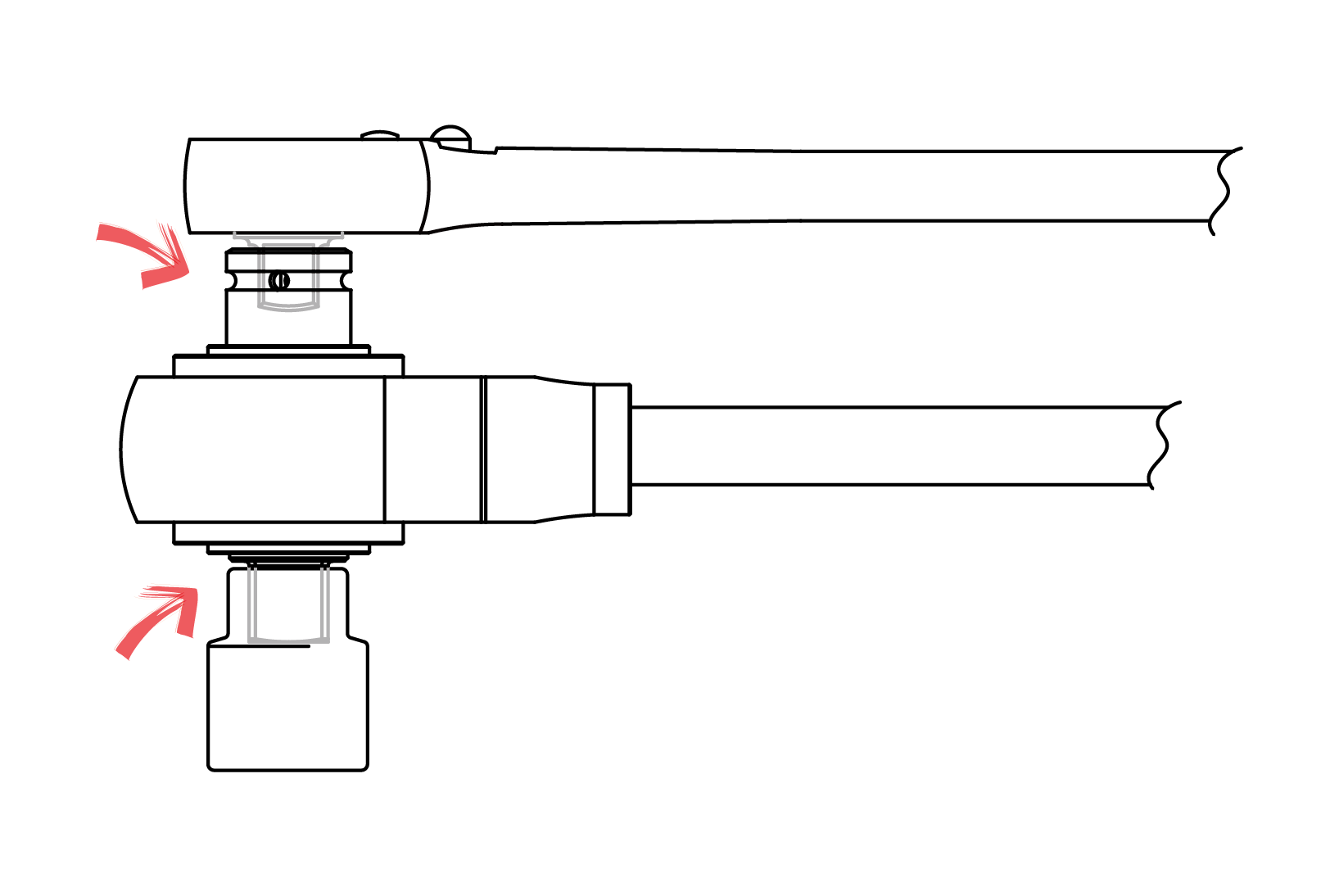

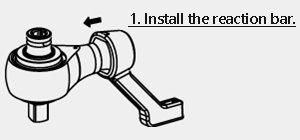

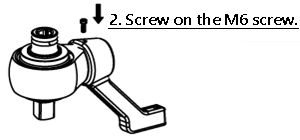

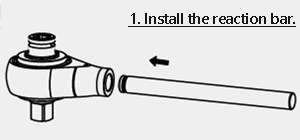

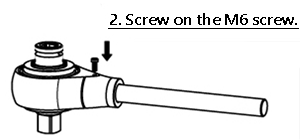

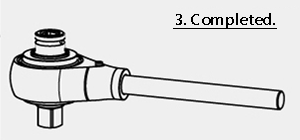

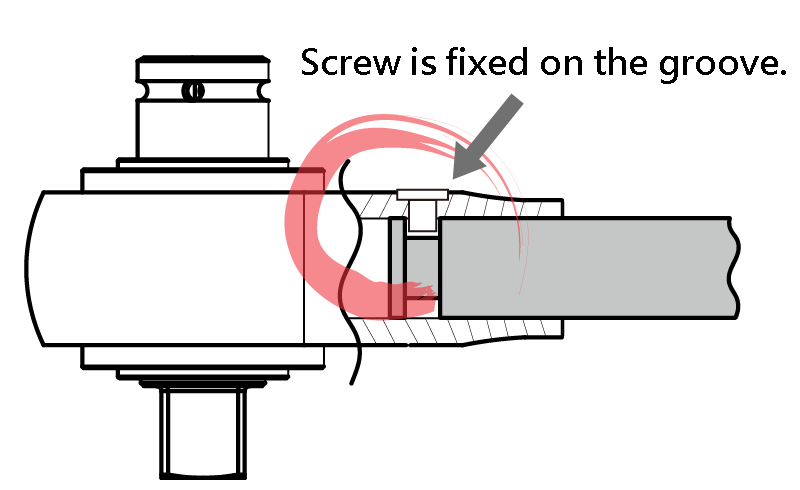

Install Steps of the Reaction Bar

|

L Type Reaction Bar |

|

|

|

|

Straight Reaction Bar |

|

|

|

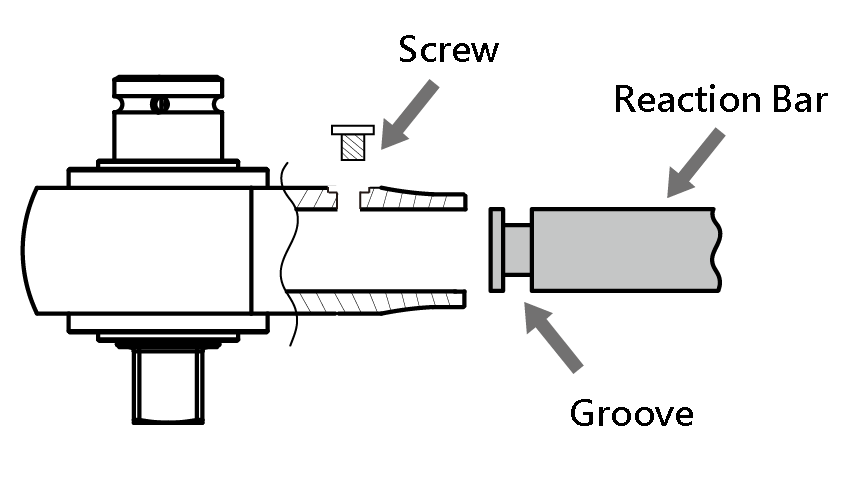

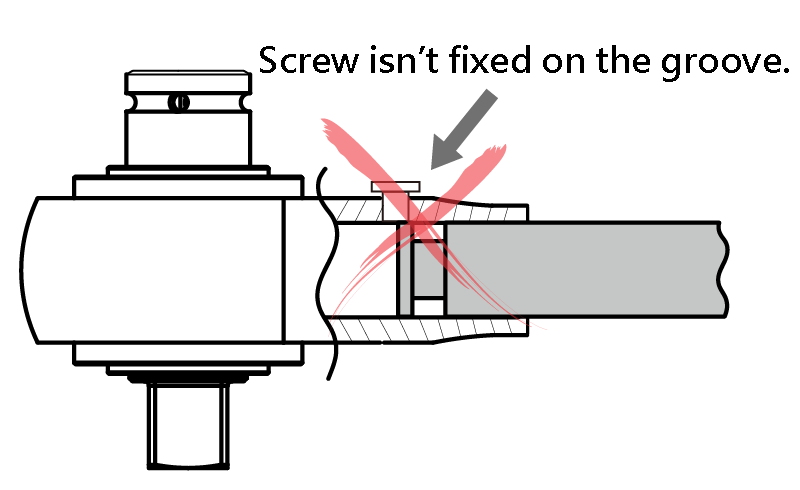

Precautions of the Installment of the Reaction Bar

|

|

|

|

※ In order to ensure the safety during the work, the screw should be properly fixed onto the groove or tapped hole of the reaction bar while installing.

Preparations

Using

After assuring the size of the object you are dealing with, set the torque multiplier and the socket according to the specification you required, then use the ratchet wrench to drive the bolts and nuts.

| Assembling Directions |

|---|

|

|

| Assembly Completed |

|

|

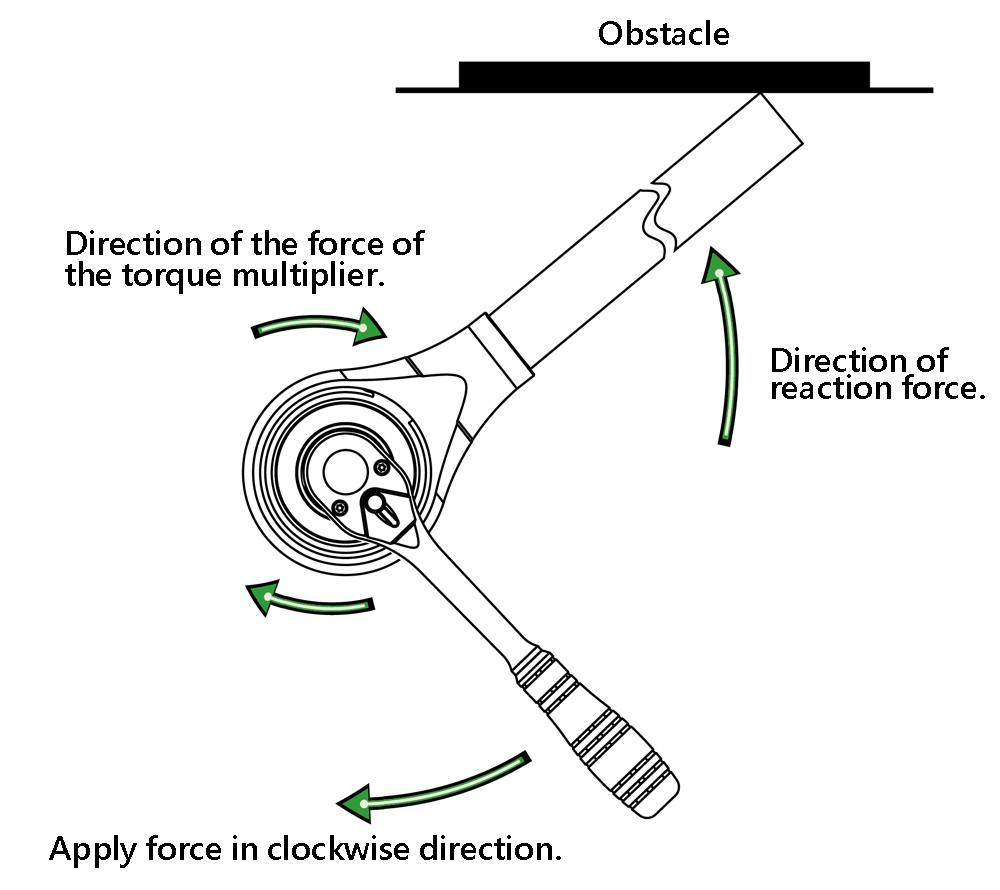

Tighten the Object through Clockwise Direction

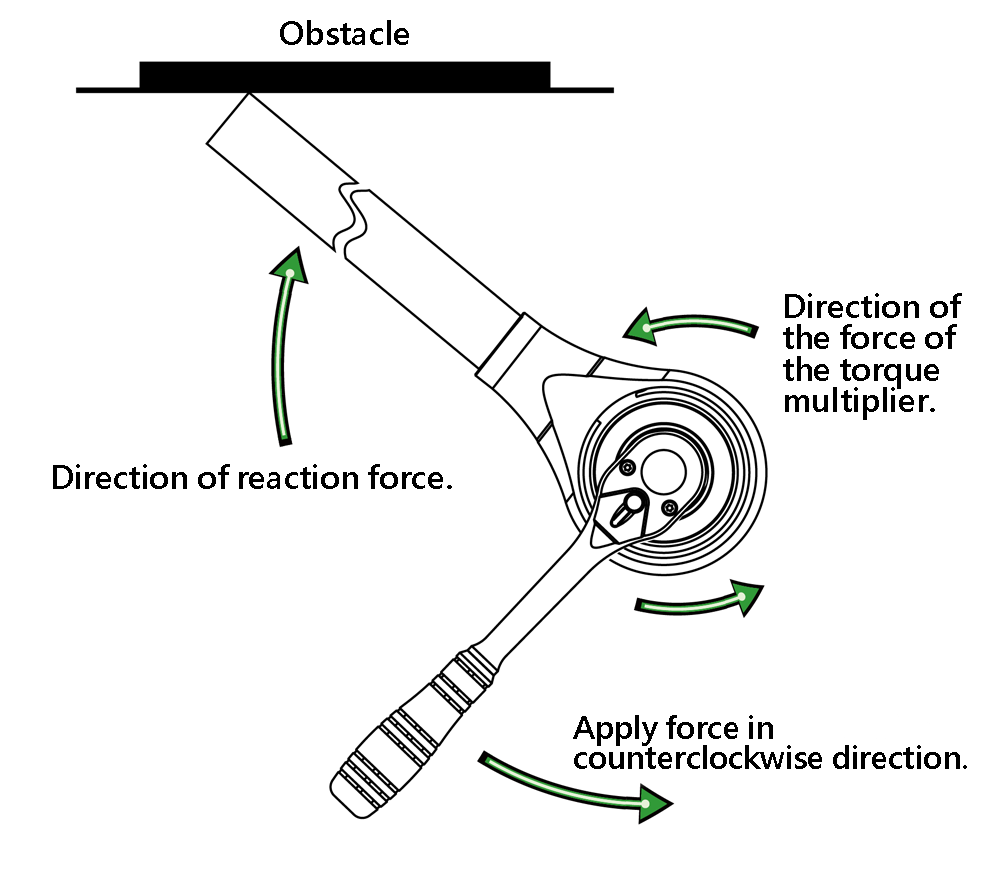

Loosen the Object through Counterclockwise Direction

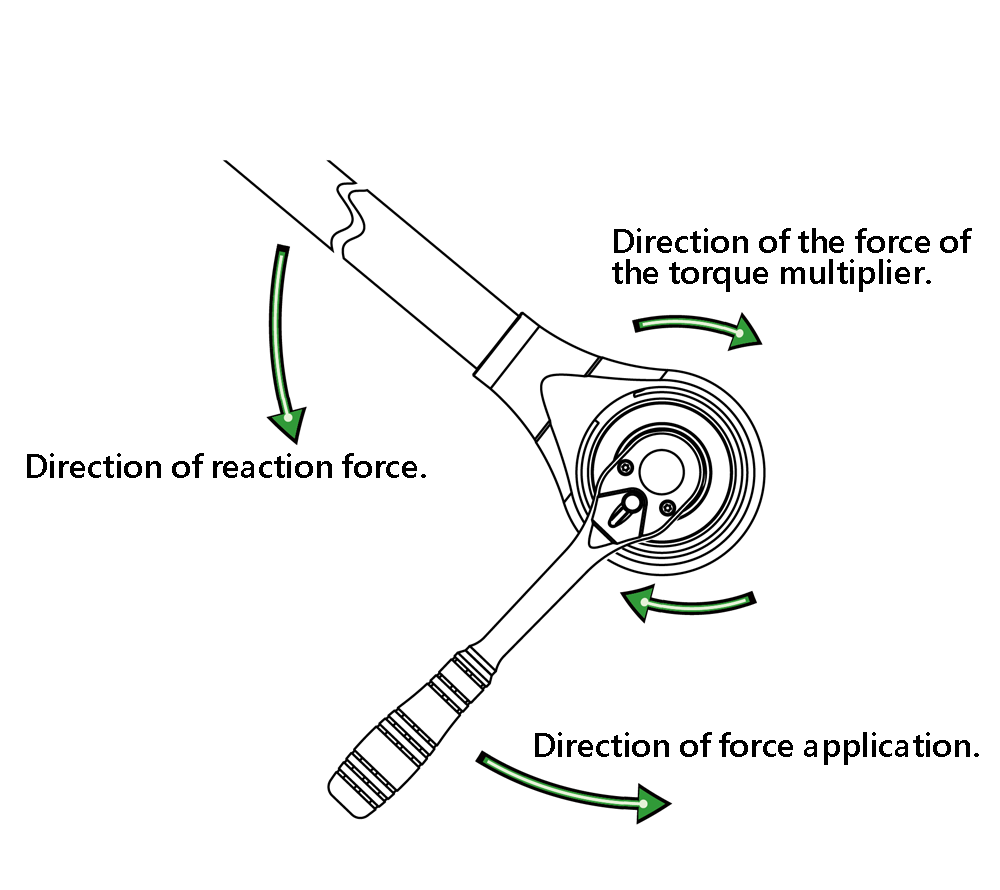

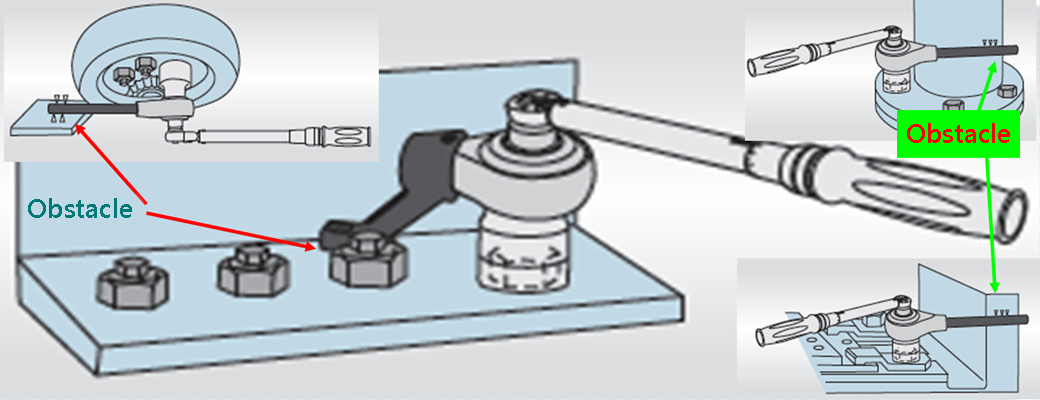

Misuse – No Obstacle is Placed Beside the Reaction Bar.

Results:

Idling situation will appear and leads to the condition of unable to tighten or loosen the objects.

It is essential for the reaction bar to lean on the obstacle firmly, otherwise the torque multiplier will present dysfunctional.

Warnings

-

The torque value of the coordinate wrench should be noticed. Please note that applying excessive torque should be avoided. (The maximum torque value of KING TONY’s products is 2700Nm)

-

The square drive of the wrench, torque multiplier and the tightening object should be placed according to the same axis as possible and remained on the position while using.

-

The attached surface of the obstacle and the reaction bar should be remained as wide as possible.

-

A right angle between the reaction force and the reaction bar should be remained as possible.

-

The point of reaction force should be away from the torque multiplier as possible and be situated in the safety triangular area.

-

Remove the wrench before disassembling the torque multiplier. The movement of striking is strongly forbidden.

-

Electric tools and pneumatic tools are strongly forbidden to be used on driving the torque multiplier.

-

Safety rope should be attached while working high above the ground.

Maintenance

-

Replace old lubricant of the interior of the torque multiplier with new lubrication every single year.

-

The reaction bar should be well taken care and should not be damaged.

Questions and Answers of the Torque Multiplier

-

Is it possible that the torque wrench can be used with the torque multiplier?

Ans: Yes, yet the torque wrench should not be considered as an accurate input value, which will caused the issue of cumulative tolerance.

-

Why can’t I regard the torque wrench as an accurate input value?

Ans: Consider the torque multipliers and torque wrenches as the same object is a common misunderstanding among general users. Even though the output tolerance of the torque multiplier is five percent, the ‘five percent accuracy’ depends on a precise input value. The tolerance of the torque wrench is four percent, which means that the tolerance will be added up to nine percent when the torque wrench is taken into account. Hence, the conclusion has emerged, torque wrenches should not be considered as the standard ‘cause the input value should be accurate and precise when using the torque multiplier.

-

Can the torque multiplier be used as a torque wrench?

Ans: The answer will be negative. Although the usage of the torque multiplier is not grounded by KING TONY, the tolerances are different between the two, which are five percent of torque multiplier and four percent of torque wrench.

-

How come the input drive should be over 3/4”?

Ans: The reason is that the maximum output value of KING TONY’s torque multiplier is 2700Nm, which means that the input value should be 540Nm, yet, a value of 512Nm, according to the standard of DIN, is a 1/2” square drive can provide. Therefore, it is necessary to use a drive that is over 3/4”.

Recommended Products

Heavy Duty Adjustable Torque Wrench (Kilogram-force Centimeter & Newton Meter)

34462-GG

Torque Multiplier(3/4"F x 1"M)

34688

Heavy Duty Adjustable Torque Wrench (English & Newton Meter)

34462-CG

3/4" DR. 24 Teeth Reversible Ratchet

6779F

3/4" DR. Flexible Handle

6452

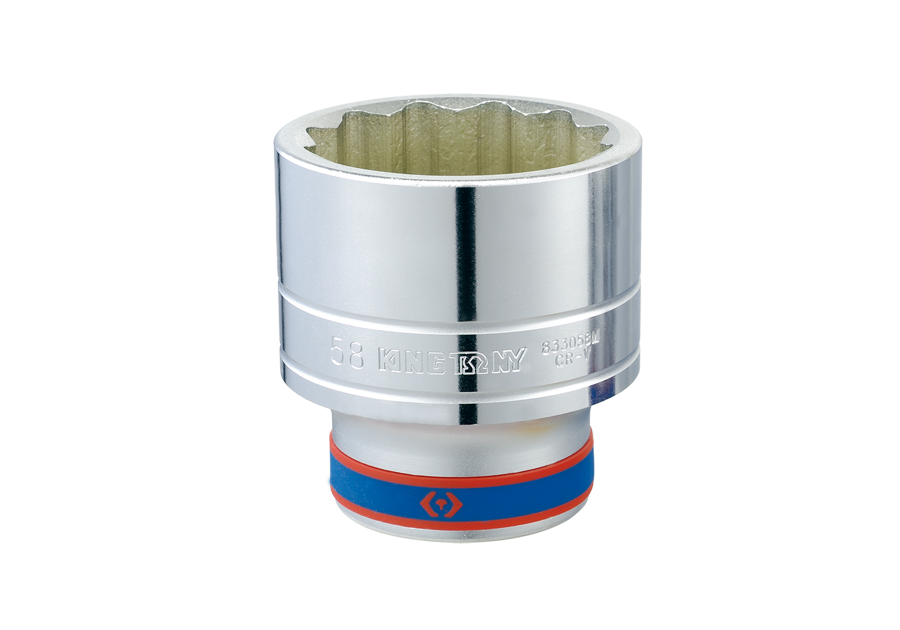

1" DR. 12 Point Metric Standard Socket

8330M

Heavy Duty Adjustable Torque Wrench (Newton Meter)

34462-DG

Heavy Duty Adjustable Torque Wrench (Newton Meter & English)

34462-FGking tony Torque multipliers are quality . But less in variation . under 4500 N.m<br />any way I recommend King Tony Torque multipliers

- masoud

- RE:Tony

- 2022-11-07 08:44:55