Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

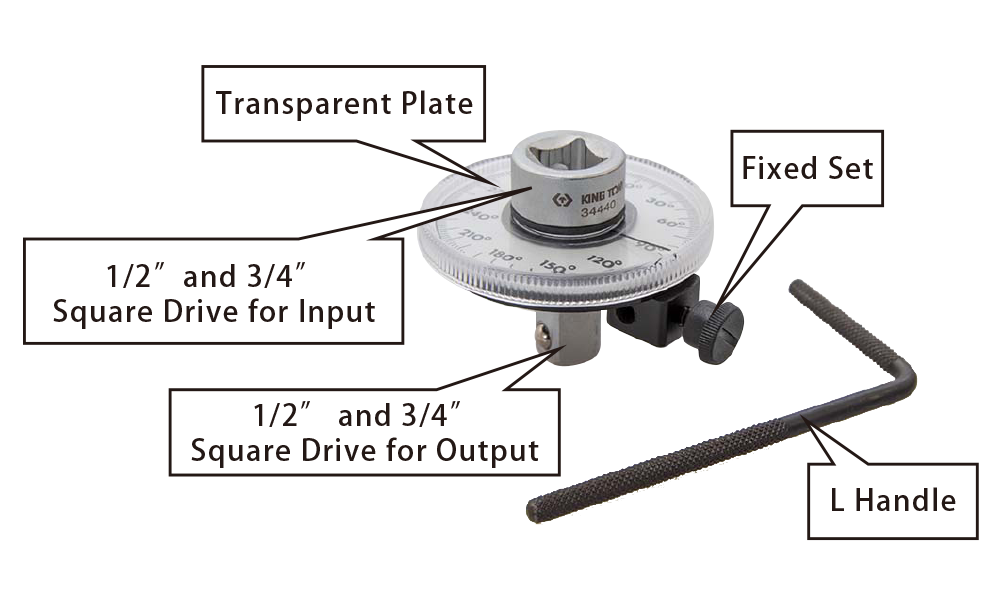

Torque Angle Gauge

Popularity : 32015Introduction

-

Uses for the screw bolts and nuts of the cylinder head and bearing cap of the interior of vehicles.

The requirements of the torque value that the screw bolts and nuts are noted on the manual. In order to avoid the issue of over tighten screws that can lead to damaged parts, from happening, utilize the torque wrench to lock up the torque value, then twist to the required value accurately. Overall, the Torque Angle Gauge is a tool that can adjust the torque value precisely and meticulously. -

The scale of the angle is 360° with a minimum of 2°. The value can be zeroed by the knob on the front and left, moreover, it is also applicable that using a 1/2” or 3/4” flexible handle to adjust the value to the angle that is mentioned in the manual.

Operating Procedures

| A | B | |

|---|---|---|

|

|

|

|

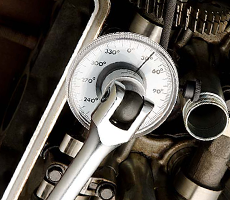

Insert the torque wrench into the target screw bolts or nut. Set up the torque value and tighten the target till reaching the required value that is mentioned in the manual. |

Put away the torque wrench, then insert the output drive of the torque angle gauge into the target screw. |

After installing the torque angle gauge, fix the L handle onto the gauge in order to stabilize it. |

| C | D | E |

|

|

|

|

Zero the indicator of the torque angle gauge. |

Insert the torque wrench onto the input square drive. |

Rotate the wrench till reaching the angle you require. For instance, if you are requiring a value of 30°, then rotate the wrench until the indicator is pointing at 30°. |