Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

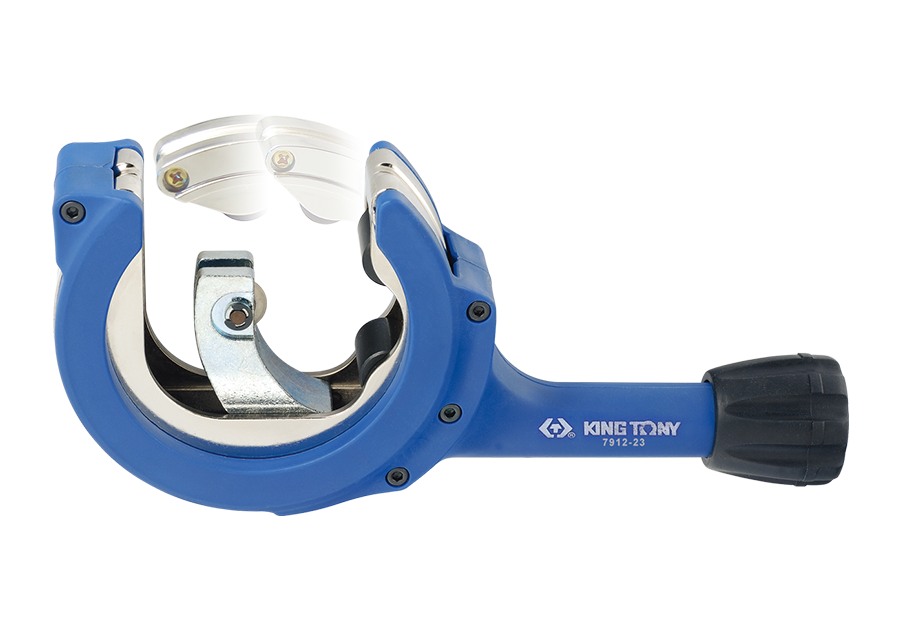

Ratchet Tubing Cutter

Popularity : 22946Ratchet Tubing Cutter

-

Goal: For cutting thin wall pipe that made of metal, such as iron, copper and stainless steel.

-

Applicable Environment: Places that require cutting thin wall iron tube, copper tube and stainless steel tube. For instance, modification of automobile exhausts, pipeline engineering installations and so on.

-

Specifications

-

Material: The body is made of zinc aluminum alloy and the blade is made of alloy steel.

-

Hardness: HRC61

-

The average error is less than 1.5mm after rotating 5 times when cutting a copper tube.

Function Descriptions

-

Rotary Button: Adjust the movement of the pipe cutting wheel. A spare cutting wheel is stored inside the button.

-

Ratchet Structure: Able to cut the tube rapidly.

-

Foldable Reamer: Trim the untidy edge easily.

Operating Steps

-

Assure the cutting position of the metal tube.

-

Adjust the open end of the tube cutter to a proper size.

-

Place the metal tube in to the cutter and align the target position with the cutting wheel.

-

Rotate the rotary button to adjust the position of the cutting wheel until the wheel slightly touches the metal tube.

-

Pull down the rotary button and rotate the tube cutter for 2 to 3 rounds, then rotate the rotary button once again. The main purpose of pulling down and rotate is to activate the ratchet function.

-

Repeat the fourth and fifth step until the metal tube is cut completely.

.png)