Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Pop Riveter

Popularity : 1016Introduction of the Rivet

´Rivet´ is a fastener that being utilized in machinery industries to fix objects permanently.

The only method to separate the fixed object is to break the rivet or damage the objects, which is different from other types of fasteners such as nails or screws. Last but not least, the technique, that use rivets to fix or set objects, is called ´riveting´.

Usage

The rivet is suitable for riveting all kinds of metal sheets and pipes that are used in manufacturing industries. It is widely being utilized in automobiles, aviation, railways, refrigeration, elevators, switches, equipment, furniture, decorations, electromechanical and light industries.

It was invented to resolve the issues that often appear when welding thin metal sheets and thin wall pipes, such as screw nuts is fusible and the internal thread is too easy to be stripped. It is really convenient that rivet can fix without tapping the internal thread and welding the nuts, and the outcome is sturdy and efficiently.

How to Use a Pop Riveter?

-

Assure the diameter of the rivet you’re setting initially. Regular specifications are 2.4, 3.0, 3.2, 4.0, 4.8, 5.0, 6.0 and 6.4mm.

-

Select the correspondent guiding nose from the accessories. General speaking, the specification will be carved onto the nose. It is a significant step to prevent the issues, such as low efficiency and rivet jamming, from happening.

-

Fully open the handle of the riveter, then tuck the mandrel, which is the thin end of the rivet, into the guiding nose.

-

Tuck the body, which is the other end of the rivet, into the hole you’re riveting. Gently pull the rivet against the objects, then apply forces to the handles multiple times until the mandrel pop out from the rivet.

| 1 | 2 | 3 | 4 |

|---|---|---|---|

|

|

|

|

| Tuck the riveter into the rivet. | Stretch the riveter. | Shrink the riveter. | Unload the riveter from the object. |

|

|||

KING TONY´s Products

-

Stainless Steel Riveter

21-20-101 21-20-07MRCapacity:

2.4, 3.2, 4.0 and 4.8mm.

Feature:

Heavy duty riveter is suitable for spacious environment and rivnuts in large sizes.

-

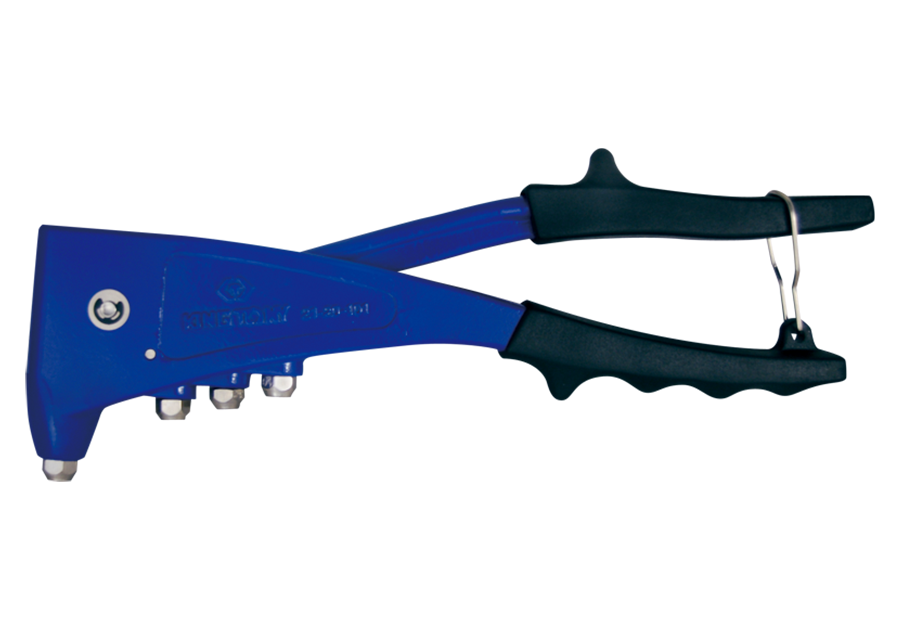

Riveter

21-20-102Capacity:

2.4, 3.2, 4.0 and 4.8mm.

Feature:

Four specifications can be switched easily and rapidly.

The adapter can be cutover between 90 and 180 degrees.

-

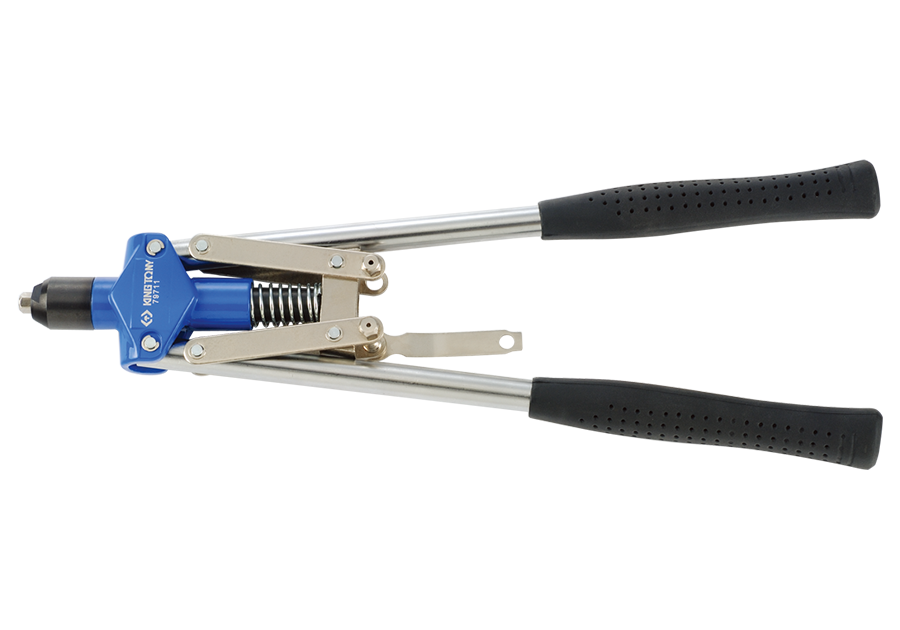

Stainless Steel Riveter

79711Capacity:

3.2, 4.0, 4.8 and 6.4mm.

Feature:

Leverage type riveter is suitable for spacious environment and rivnuts in large sizes. It is also capable of dealing with stainless steel and aluminum rivets.

-

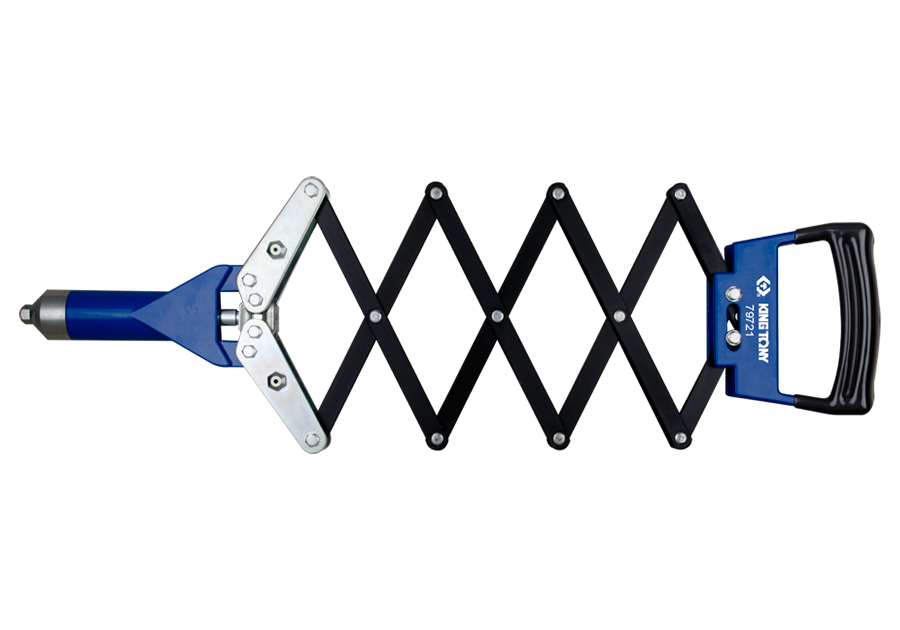

Riveter

79721Capacity:

3.2, 4.0, 4.8 and 6.4mm.

Feature:

Retractable riveter is suitable for spacious environment and rivnuts in large sizes.