Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Pneumatic Tools Introduction

Popularity : 1878Pneumatic Tools

Pneumatic tools consider compressed air as the source of propulsion. Using air to drive the motive parts to generate energy and torque in order to build machines that can perform a variety of movements. Pneumatic tools are widely used in almost every machinery and relevant industries. For instance, the industries of automobile repairing, computer electronics, mechanical assembly, molding, woodwork and construction, are industries that used pneumatic tools heavily.

Styles of Pneumatic Tools

-

Rotating Style: Impact wrenches, Impact screwdriver...

-

Non-rotating Style: Impact nail gun, Impact scissors...

-

Reciprocating Style: Pneumatic reciprocating polishing machine, pneumatic saw, Air hammer...

-

Pulling Style: Air threaded insert riveter, Air pop riveter, Huck pneumatic rivet gun...

-

Right-and-left Style: Air right and left lapper, pneumatic glass seal cutter...

-

Other Style: Pneumatic oil lubricator, Pneumatic filter, Air blow gun...

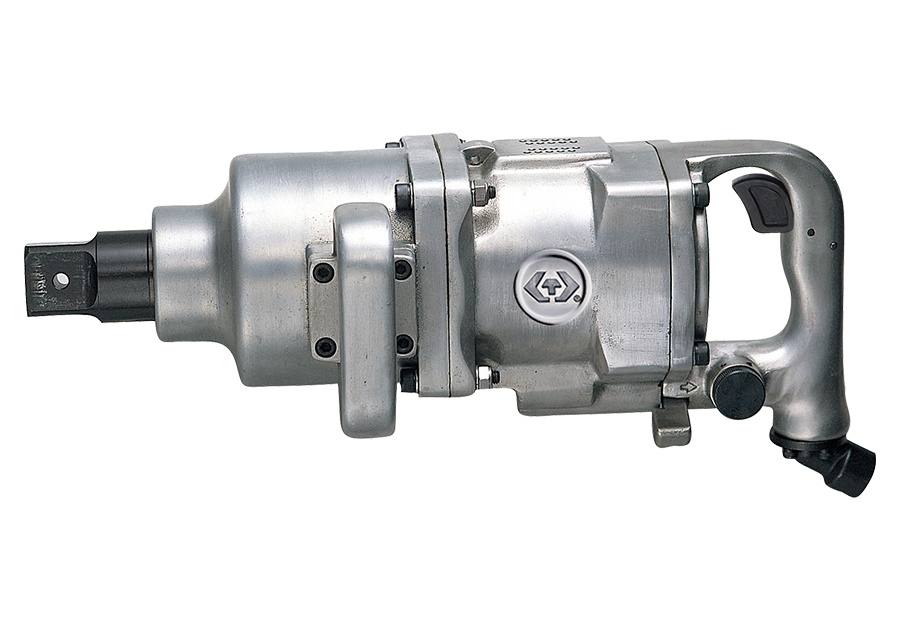

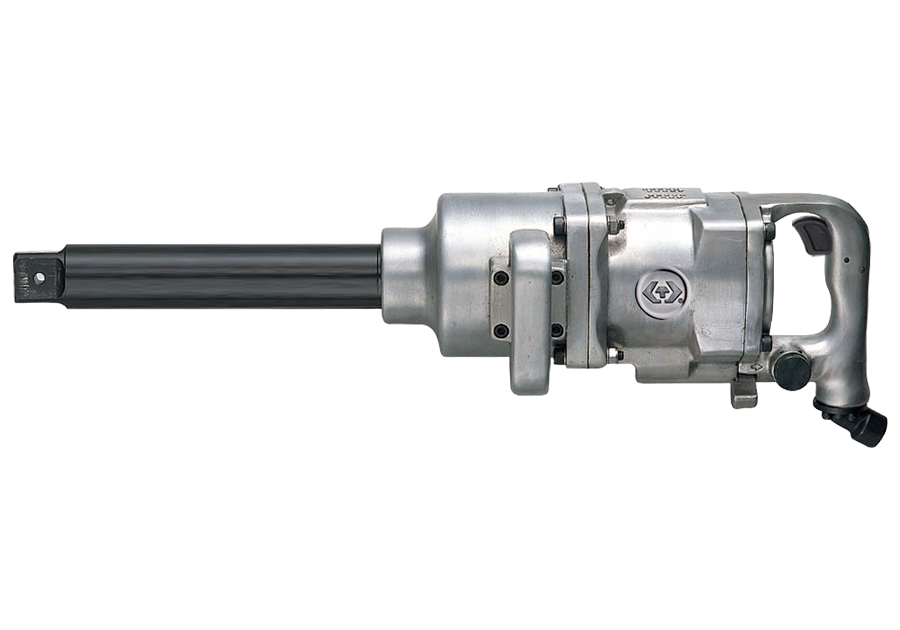

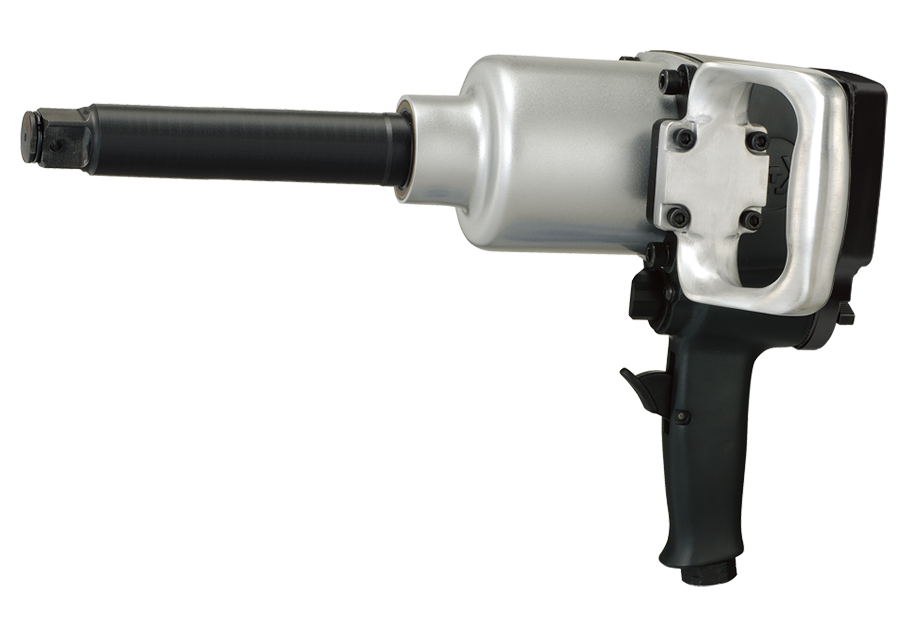

The type of Impact wrenches is the most used and popular tool in all pneumatic tools. How to choose the impact wrench that is suitable for you and make your work time-saving and effort-saving? The table below demonstrates the product specifications that will normally be tagged on the impact wrenches.

| Square Driver | Std. Bolt Size | Free Speed | Max Torque | Overall Length | Air Inlet | Air Hose | Air Consumption | Noise Level | Vibration |

|---|---|---|---|---|---|---|---|---|---|

| Inch | Inch (mm) |

R.P.M | FT/Lbs (N.M) |

Inch (mm) |

NPT | ID | CFM. (L/min) |

DB (A) |

M/S² |

| 1/2" | 5/8 (16) | 8000 | 400 (542) |

7-1/8 (180) |

1/4" | 3/8" | 4.2 (119) |

95 | 3.6 |

-

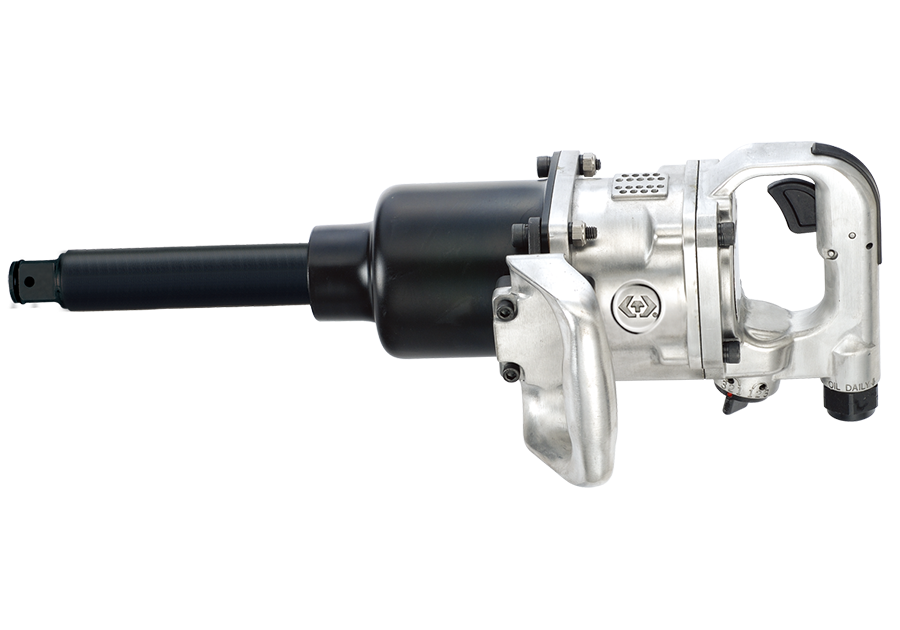

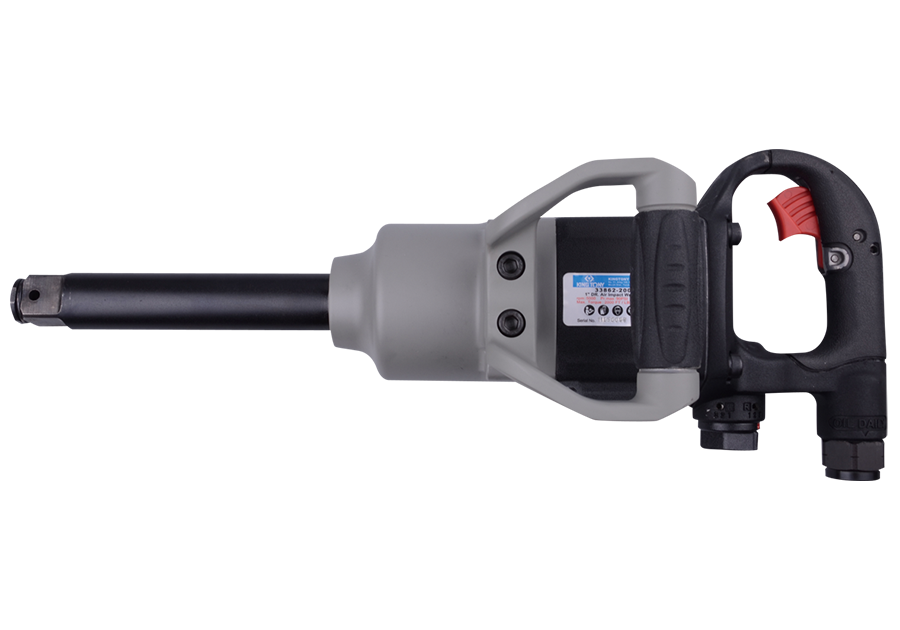

Square Driver: Depicts the specification of the component that is circled in Picture 1.

-

Free Speed: The unit is RPM, represent Revolution per minute.

The higher the speed is, the fewer time to finish the work. (Higher speed means the increase frequency of hammering components and the elevate of boosting the torque.) -

Max Torque: The higher the torque is, the fewer effort to finish the work.

When the torque of a locking screw is higher than the highest torque of the corresponding impact wrench, not only the work will be time consuming, but also the failure of removing the screw will occur the overheat of the wrench and increase the wear and tear of the hammering components.

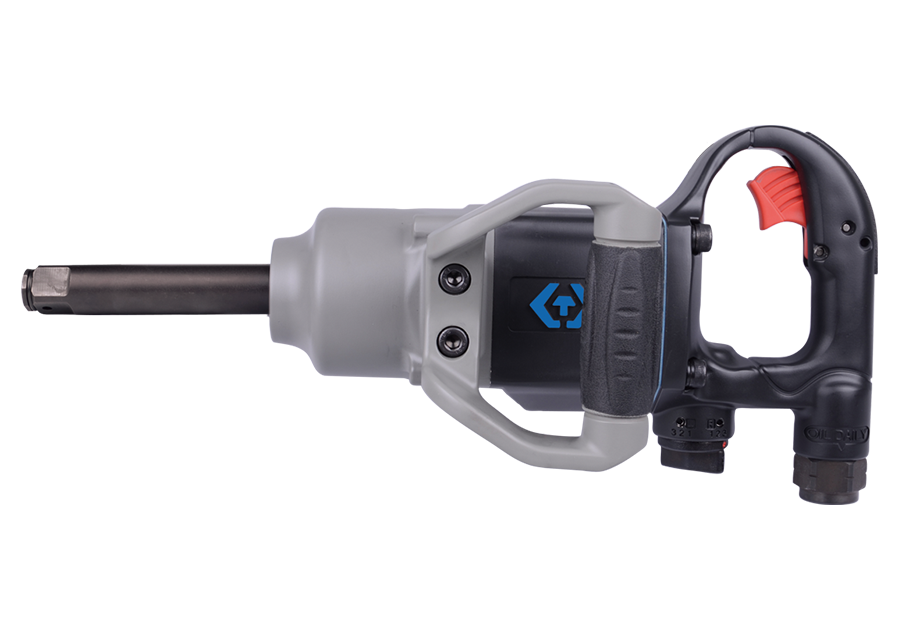

Picture 1

General Specifications

| Vehicles | For general vehicles repairing. Regular specifications: 3/8" DR, 1/2" DR, 3/4" DR and 1" DR. |

|---|---|

| For special vehicles repairing, such as tracked vehicles, tanks, excavator and large-scale engineering vehicles. Regular specifications: 1-1/2" DR. |

|

| Industrials | Mechanical assembly line. Regular specifications: 3/8" DR and 1/2" DR. |

| Constructions and steel structure conjugations. Regular specifications: 3/8" DR and 1" DR. |

|

| Shipbuilding and repairing. Regular specifications: 1-1/2" DR. |

|

| Large-scale heavy machines installing and repairing. Regular specifications: 2" DR. |

Beside the square driver, free speed and torque that mentioned above, the air pressure while working is also significant. As the matter of fact, the working air pressure of a general impact wrench is 90PSI. When the air compressor generates the pressure under 90PSI, the output of the pneumatic tools will be descended. On the contrary, pressure over 90PSI will decrease the service life of the components inside the impact wrench, which illustrates that the pressure that generated by air compressor should be assured when using pneumatic tools.

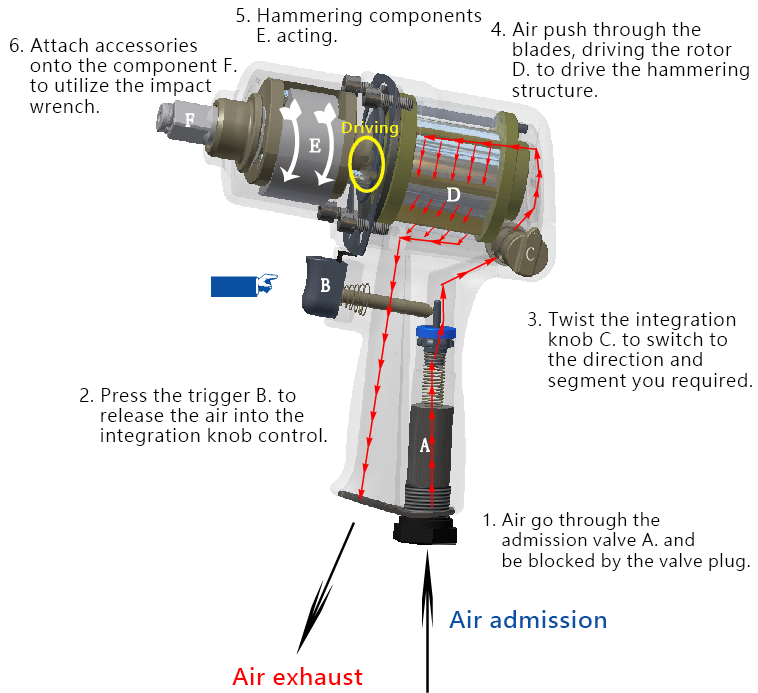

The Actuation Graph of an Impact Wrench

Detailed descriptions are in KING TONY E-learning website.

Impact wrenches Precautions

The procedures of using an impact wrench are no more than turning on the air compressor, connecting the impact wrench with air hose and attaching the socket. Easy, normal and simple. However, ignoring these processes will lead to low efficiency and the descending of service life of the product.

Please note the cautions below while using impact wrenches.

-

Air tool oil is to clean, lubricate and antirust pneumatic tools. Before using the pneumatic tool, pour 2-3 cc of air tool oil into the tool from the air admission port and function it freely for a few seconds. Add a couple times of air tool oil in the middle of long-term using can cool down the tool and maintain the operation smoothly.

-

The renewal of grease should be implemented every three months. Adequate amount will be enough because the excessive fill will decrease the efficiency of the tools. In addition, tools with oiling port should remove the screws and refill with small amount of grease every month in order to lengthen the service life of the hammering clutch.

-

Please note that despite the higher air pressure can elevate the torque of the tools, the service life of the tools can be reduced due to the excessive air pressure. The combination of cleaned, low temperature and dehydrated compressed air with standard air pressure is significant in maintaining the service life of the tools.

-

Pneumatic tools require cleaned, low temperature and dehydrated compressed air. In fact, even though the impurities and the moisture are removed from the air compressor, a few of them might still be left inside the pipes and hoses. Although the situation can be improved by installing the combination of three (water filter, oil applier and pressure adjuster) onto the pipes and hoses, exhausting the moisture and impurities from the compressor cylinder frequently is still the one and only way.

-

From the combination of three to the impact wrench, the distance should be under 4.5 meters, or the excessive length will affect the delivery of the air pressure and caused the issue of lack of energy.

-

Please only attach impact sockets and not hand sockets onto the impact wrenches. The thickness of hand sockets is thinner than impact sockets, which implies that the force of the impact wrenches might be too strong to break the hand sockets.

-

When using pneumatic tools, the air pressure shouldn’t be over the working pressure (90psi).

Conform to the instructions above exactly can retain the service life of the impact wrench in order to make sure the work won’t be delayed because of the dysfunctional of the tools.