Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Know the hand socket and impact socket

Popularity : 19661Understanding Hand Socket and Impact Socket

Sockets are divided into hand socket and impact socket, and both kinds are produced for disassembling outer angle screw nuts safely and rapidly.

| About Hand Socket | |||||

|---|---|---|---|---|---|

| Screw Shape | |||||

| Square Drive Size | 1/4" (6.35 mm) 3/8" (9.52 mm) 1/2" (12.7 mm) 3/4" (19.05 mm) 1" (25.4 mm) 1-1/2" (38.1 mm) 2-1/2" (63.5 mm) 3-1/2" (88.9 mm) | ||||

Types

Normally are divided, according to the unit of the screw hole, into Metric and Imperial.

Differences of the Impact Socket between Continents

Typical Styles of Sockets

| Styles | Usage | Industries |

|---|---|---|

| For disassembling outer hexagonal or 12 points screws. | Factories, automobile and locomotive repairing and machinery assembly. | |

| For disassembling outer hexagonal or 12 points screws. | Factories, automobile and locomotive repairing and machinery assembly. | |

| ’Universal Joint’ is also known as ‘Universal Coupling’, which is a mechanical linkage that transfer the rotation between the two axis. During the transferring, the amount of the angle of the intersect axis can float in a certain range. | Factories, automobile and locomotive repairing and machinery assembly. | |

| For disassembling the spark plugs. | Automobile and locomotive repairing. | |

| For disassembling the star screws of the automobiles or locomotives. | Automobile and locomotive repairing. | |

| For disassembling screws that are in specific angles. | Factories, automobile and locomotive repairing. |

Differences between Hand Socket and Impact Socket

| Hand Socket | Impact Socket | |

|---|---|---|

| Specification Accordance | DIN-3124 | DIN-3129 |

| Square Drive Accordance | DIN-3120 | DIN-3121 |

| Screw Hole Accordance | DIN ISO-691 | DIN ISO-69 |

| Groove | Inner groove | Pin hole |

| Usage | Utilize with hand tools, such as ratchets or torque wrenches in order to loosen or tighten the outer hexagonal screw bolts or nuts. | Utilize with pneumatic or electric tools, such as impact wrench, impact ratchet or electric wrench in order to loosen or tighten the outer hexagonal screw bolts or nuts. |

| Speed / Torque | Low / weak | High / strong |

Recommended Products

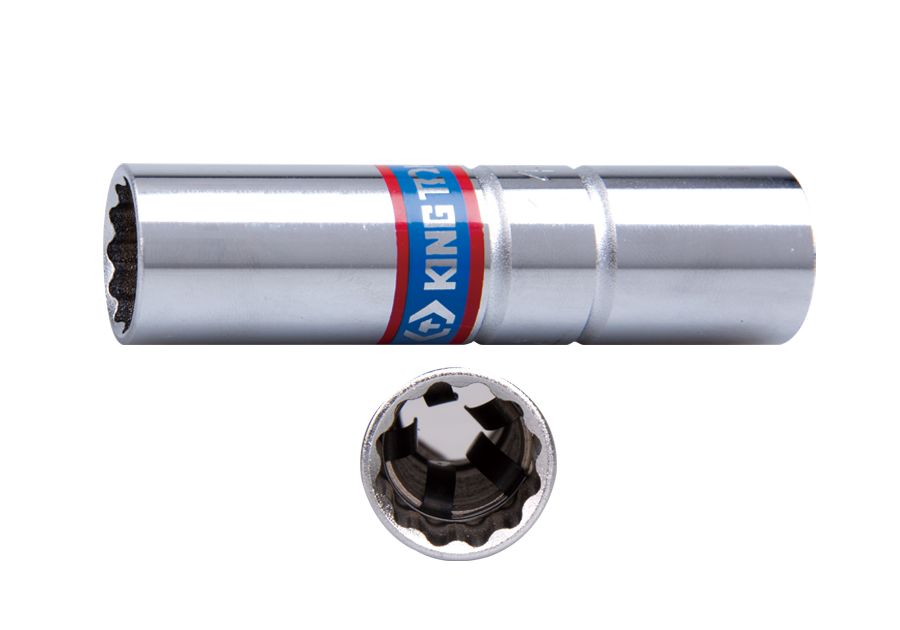

1/2" DR. 12 Point Metal Clip Spark Plug Socket

4670

1/2" DR. 12 Point Inch Standard Impact Socket

4530S

1/2" DR. 12 Point Inch Deep Impact Socket

4430S

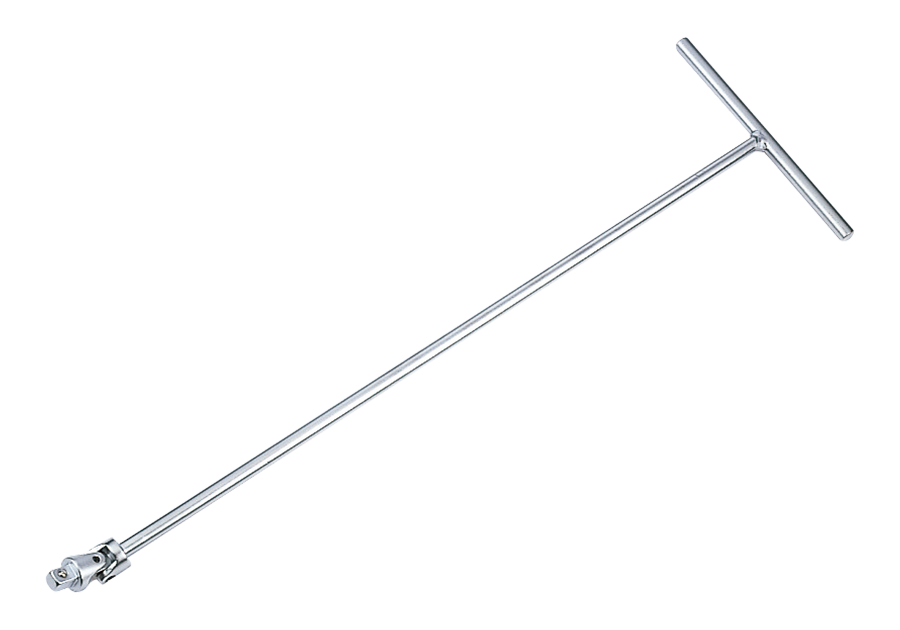

1/2" DR. T-shaped Universal Joint Driver

4795

1/2" DR. 12 Point Metric Standard Impact Socket

4530M

1/2" DR. 12 Point Metric Deep Impact Socket

4430M

1/2" DR. 12 Point Metric Deep Socket

4230M

1/2" DR. 6 Point Metric Deep Socket

4235M

1/2" DR. Star Socket

4375M

1/2" DR. Universal Joint

4791R