Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

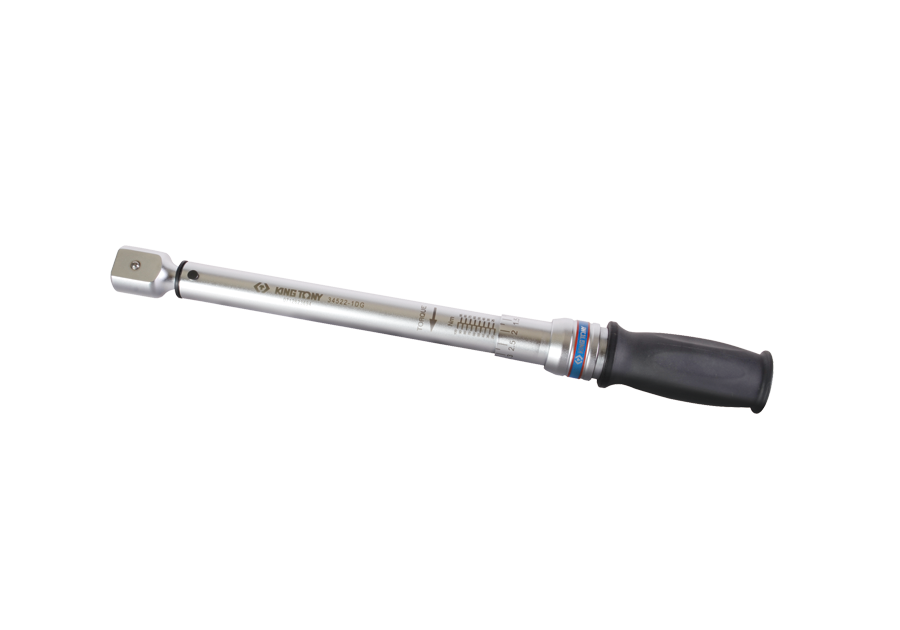

KING TONY Torque Wrench Series

Popularity : 177823KING TONY Torque Wrench Introduction

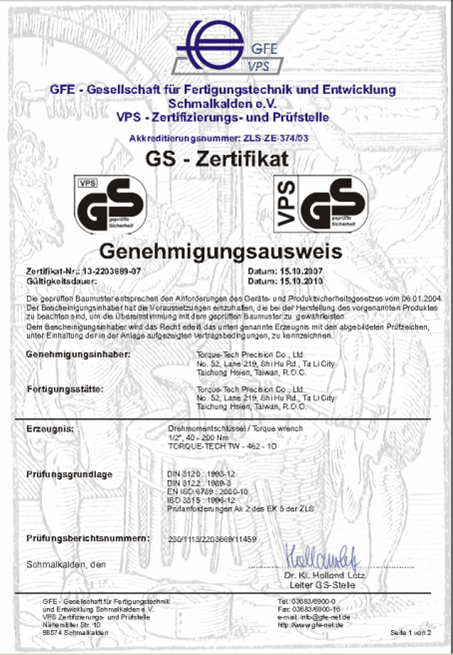

KING TONY’s torque wrenches are manufactured and tested following the international standard, DIN ISO 6789, and have acquired the GS Certificate.

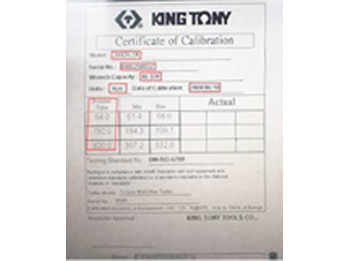

Standard operating procedures are followed while manufacturing. Every torque wrench, after the assembly, should be calibrated according to the DIN ISO 6789 in order to make sure the torque is in line with the regulation.

The tests and inspections that KING TONY implemented are different from our same trades, which are running the calibration through machinery equipment instead of manual calibrating to avoid the inaccuracies because of the negligence of human operating.

The Types of Torque Wrench

KING TONY’s torque wrenches can be divided into Industrial Class and Professional Class according to the accuracy, service life and using frequency of the users.

| Industrial | Professional |

|---|---|

| Industrial Type Elongated Type 72PT Type Mini Type Torque Screwdriver | Professional Type Classic Type |

Industrial Class

| L Type | Elongated Type | 72PT Type |

|---|---|---|

| 34462-CG 34462-DG 34462-EG 34462-FG 34462-GG 34466-FG | 34862-2C 34862-2D 34862-2E 34862-2F 34862-2GG 34862-3CF 34862-3FF | 3446A-DG 3446A-EG |

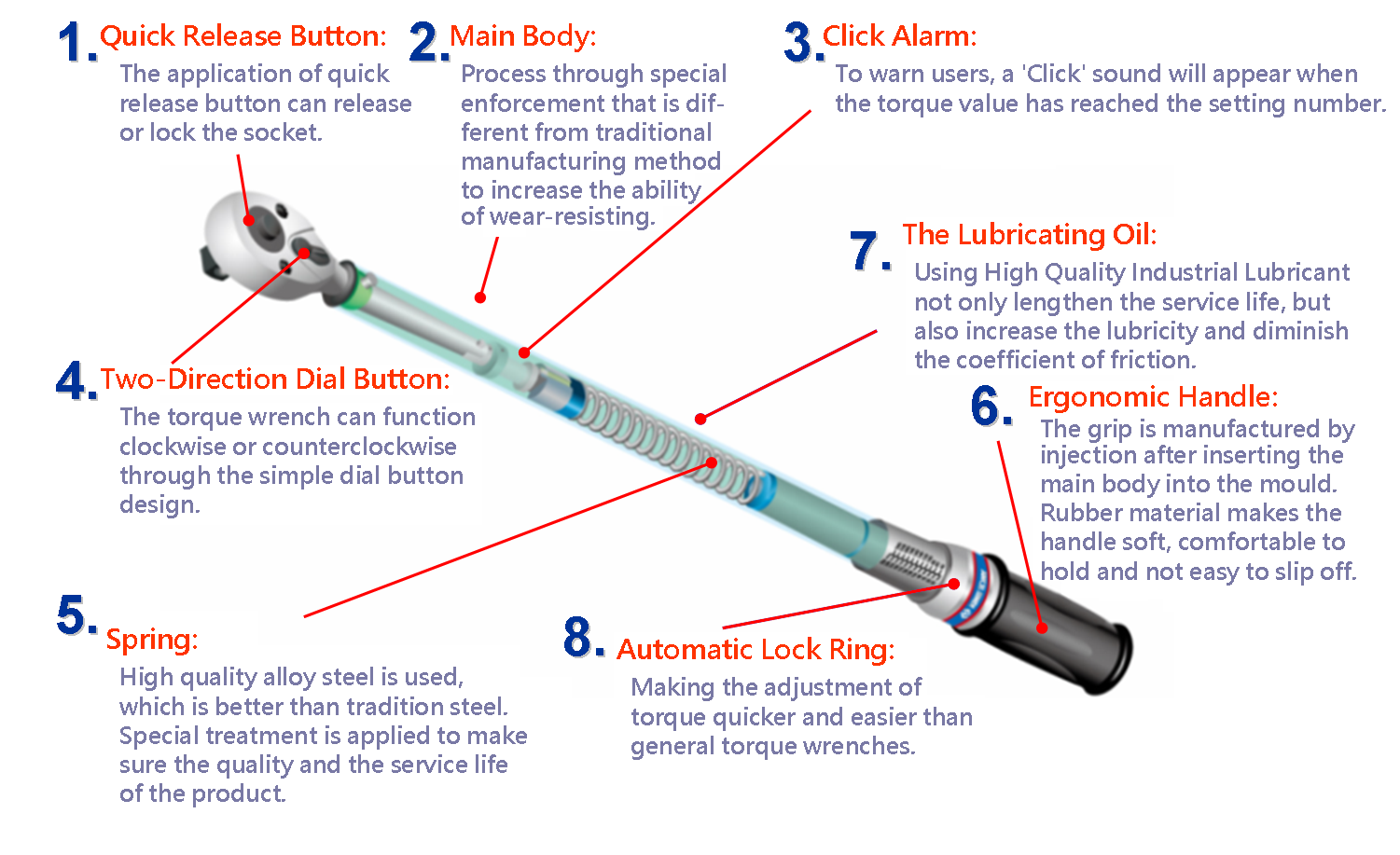

The Features of the L Type Torque Wrench

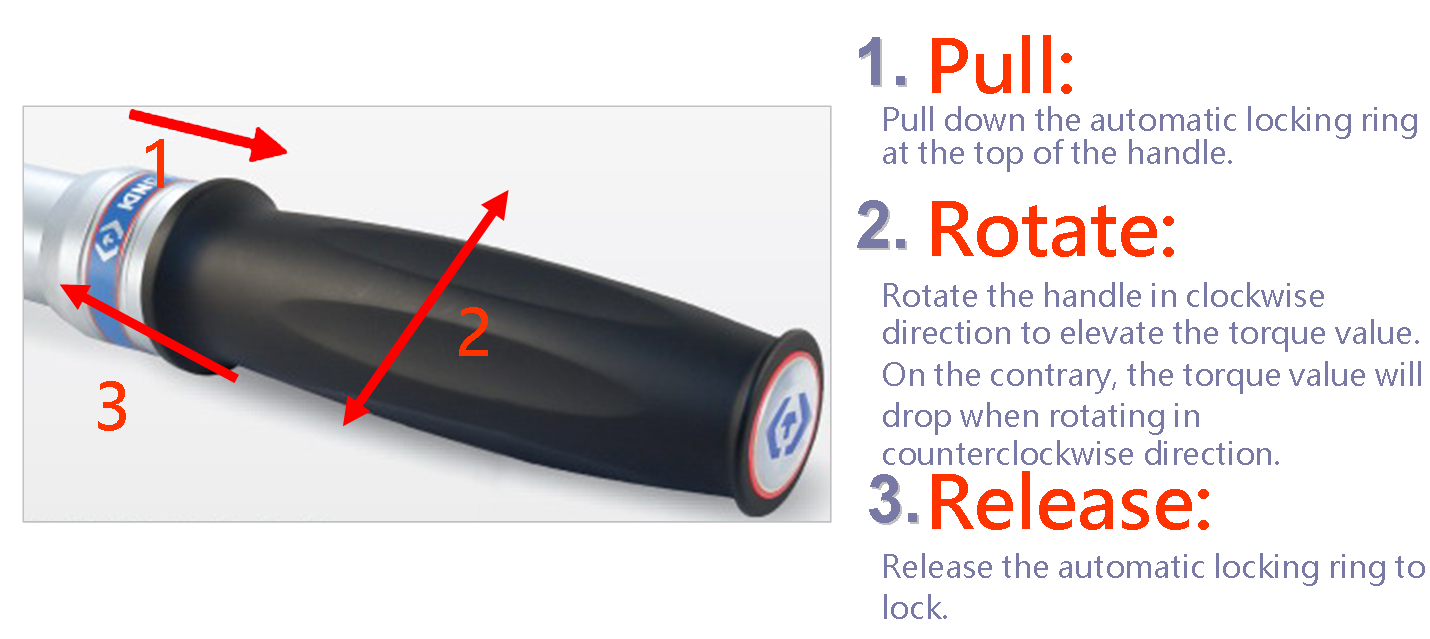

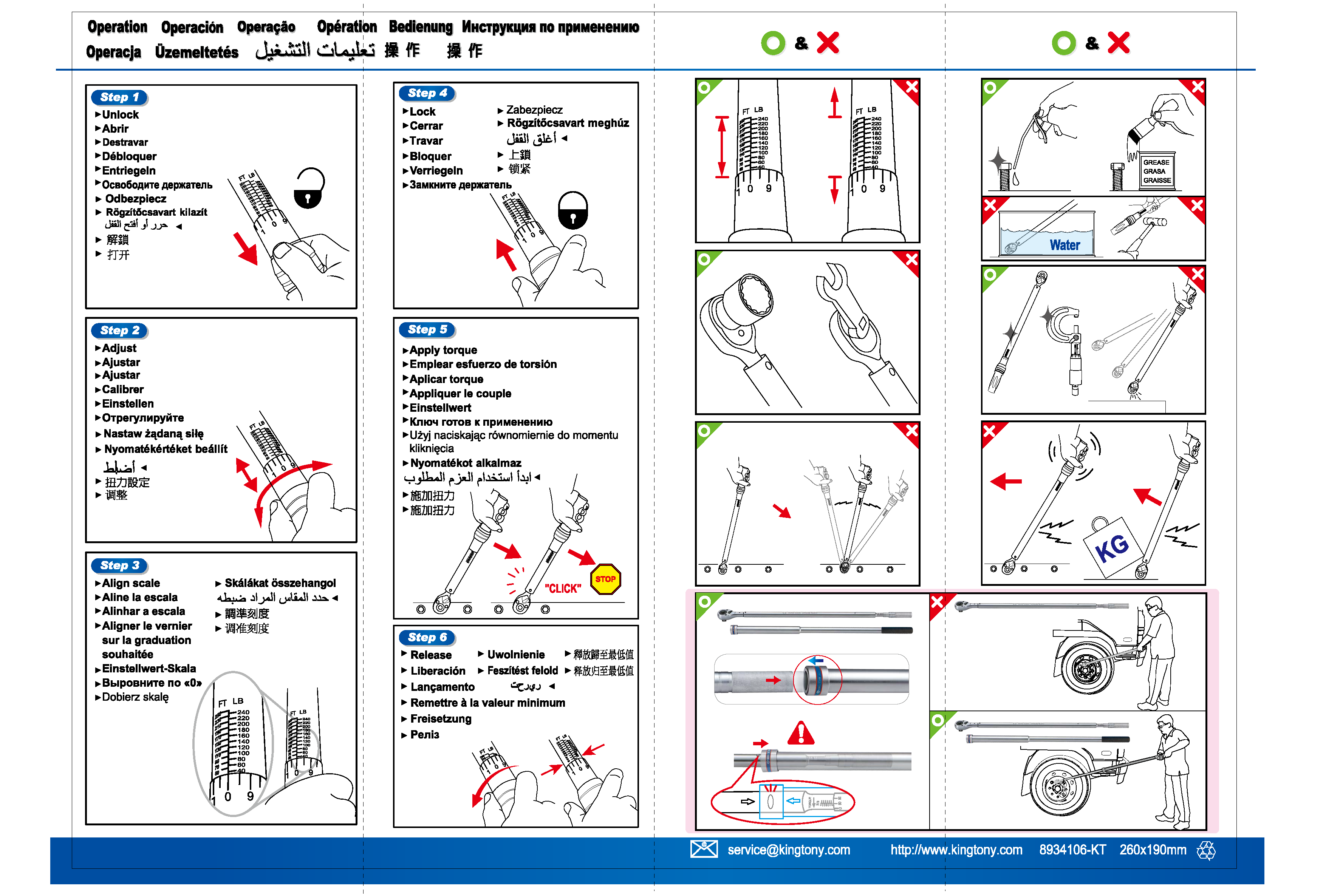

Operating Instructions of the L Type Torque Wrench

Differences - Head

| KING TONY | Others | ||

|---|---|---|---|

|

|

|

|

Differences – Main Body

| KING TONY | Others |

|---|---|

Rounded (dual directions) |

Depressed (single direction) |

Differences – Setting the Torque Value

| KING TONY | Others |

|---|---|

|

|

Differences - Scale

| KING TONY | Others | |||

|---|---|---|---|---|

|

|

|

|

|

Differences – Calibration and Tests

-

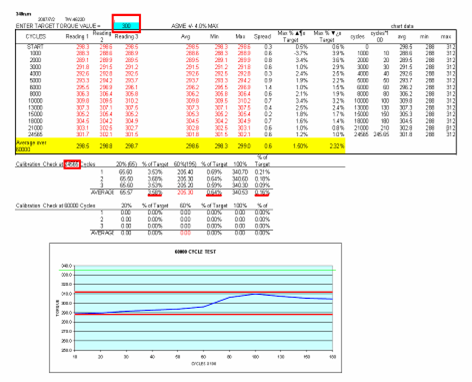

Utilize specific calibration facility according to different specifications.

-

The calibration facility will be adjusted every six months in order to assure the accuracy of the machine.

-

Automatic calibration facility can avoid the inaccuracies of manual operation.

-

The calibration processes are following the regulations of international standards.

Certificate of Calibration

GS Certificate

Test report

Suitable Field for Torque Wrenches

| Class | Type | Suitable filed |

|---|---|---|

| Industrial class |

L Type |

Industries, Aerospace, Lab facilities and Vehicle industries. |

|

Interchangeable Type |

Industries, Aerospace, Lab facilities and Vehicle industries. |

|

|

72PT Type |

Industries, Aerospace, Lab facilities and Vehicle industries. |

|

|

Mini Type |

Locomotive, Bicycle industries and Laboratory facilities. |

|

| Professional class |

Traditional Type |

Vehicle and Machinery industries. |

|

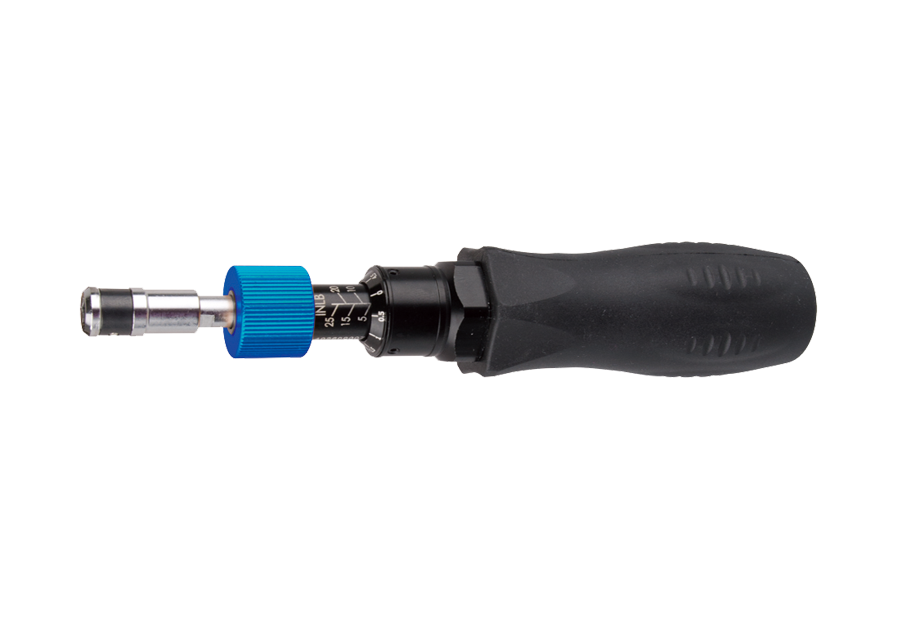

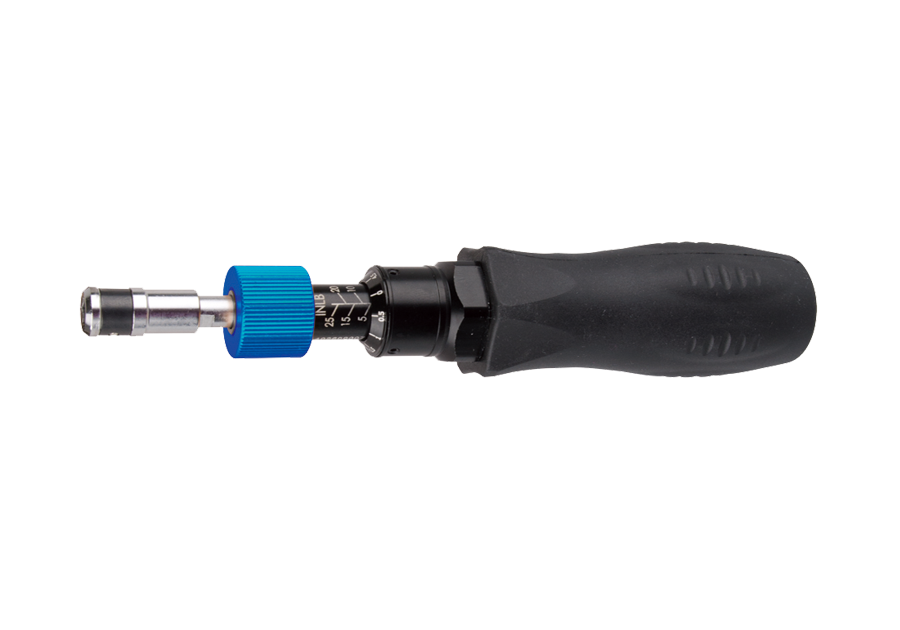

Torque Screwdriver |

Computing facilities, Bicycle industries and Precision Instruments. |

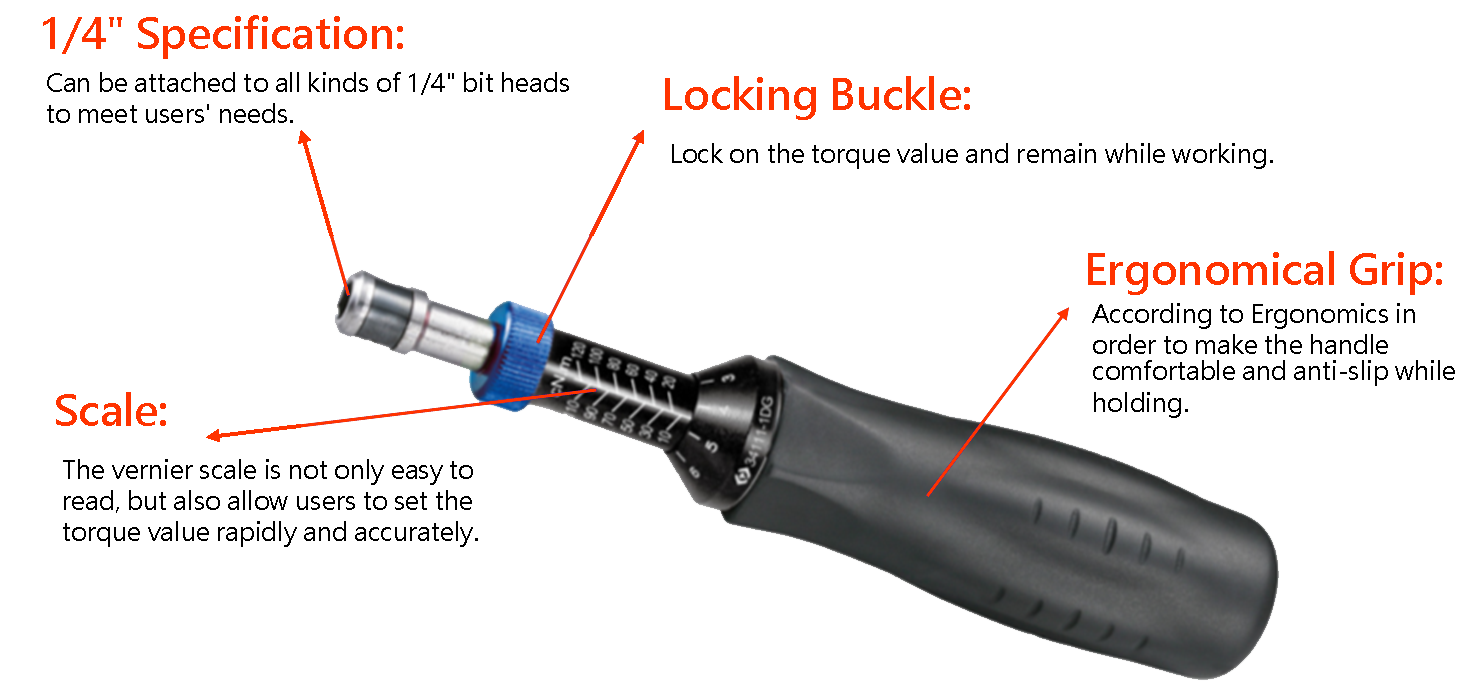

The Features of Torque Screwdrivers

- The torque screwdriver is featured with neck post bearing type trip mechanism structure, which implies that the times of tripping, when the torque value is reached, is unlimited, hence the issue of overtighten can be prevented. Nevertheless, the structure can be utilized by both directions.

- The weight of the torque screwdriver is greatly decreased due to the material we used, Aluminum Alloy.

- The torque screwdriver is equipped with two thrust needle ball bearings and one steel ball bearing, which can efficiently lower the coefficient of friction, to approach a torque value with higher stability.

6 Main Reasons that Affect the Quality of Torque Wrenches

- Main body:

The main bodies that had been through special manufacturing process perform better wear-resistant when rubbing along with interior components, and leads to a torque value with higher accuracy. KING TONY’s products had been through the special manufacturing process. - Spring:

Different material performs different durability. General wrenches are made with normal materials, on the other hand, KING TONY’s wrenches used special high quality alloy steel to make sure the spring rate and service life of the spring. - Lubrication:

The coefficient of friction will be generated when the main body and the components are actuating, yet it can be decreased by using the lubrication with fine quality. KING TONY utilize High Quality Industrial Lubricant to lengthen the service life, increase the lubricity and diminish the coefficient of friction. - Assembly:

Torque wrench is consisted of multiple precision components, therefore, the attitude of assemblers can affect the quality of the products. KING TONY’s assemblers need to attend specific training sessions before the official assembly in order to assure the quality of the products. - Tolerance:

Tolerances can appear in every piece of component, hence controlling the tolerance of the product in an acceptable range is a significant erudition. From designing to manufacturing, KING TONY’s torque wrenches had been through countless deliberations and computer aid designs to make sure the quality of our products is higher than our other trades. - Calibration:

The torque value of the torque wrenches should be calibrated before leaving the factories so that the quality of the torque wrenches can be assured. KING TONY’s products take the accordance of DIN ISO 6789 as priority, in addition, to make sure the quality of each piece, use the automatic calibration facilities to calibrate the products.

The main body infers to skeleton, the spring infers to heart and the lubricant infers to blood, which implies that different compositions will lead to different qualities.

Operating Precautions

-

The torque value should be reset to zero after using in order to avoid the issue of elastic fatigue of the spring and affect the accuracy of the torque wrench.

-

Do not use the torque wrench as a disassemble tool or the interior components might be damaged.

-

Avoid heavy falls.

-

When encountering abnormal situations while using, assure whether the components of the head are functioning first. If the head is performing normally, the issue may be the damaged of the interior components, which requires the repairing department to resolve the problem.

-

Torque products must be regularly returned to the impartial unit for torque calibration to ensure accurate torque values. The recommended calibration time is one year of use or more than 5,000 uses.

-

In order to assure the accuracy of the torque value and avoid troubles while using, do not arbitrarily disassemble any components inside the main body.

Warning

DO NOT OPERATE THE TORQUE WRENCH NEAR THE HIGH VOLTAGE ELECTRICITY FACILITIES!!

Recommended Products

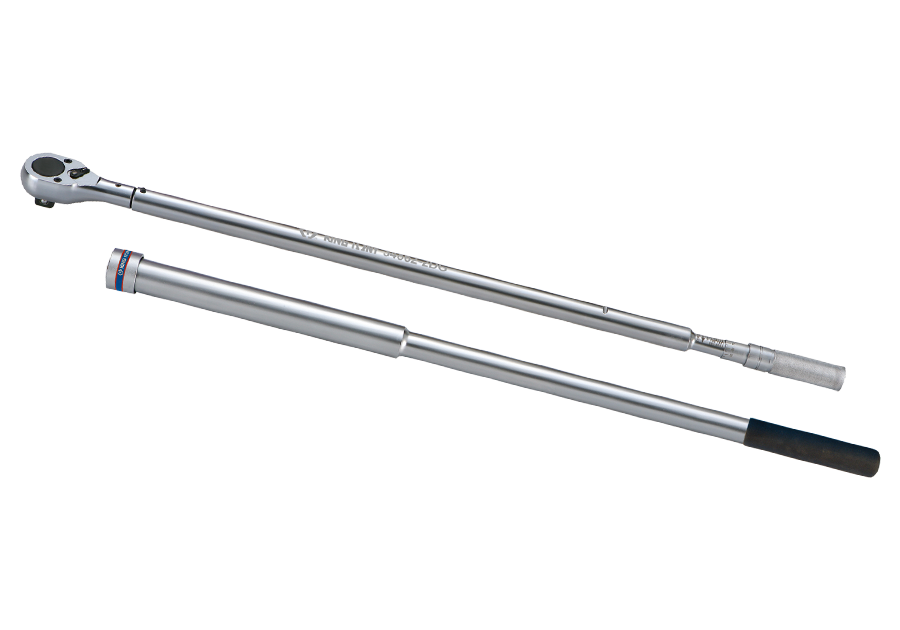

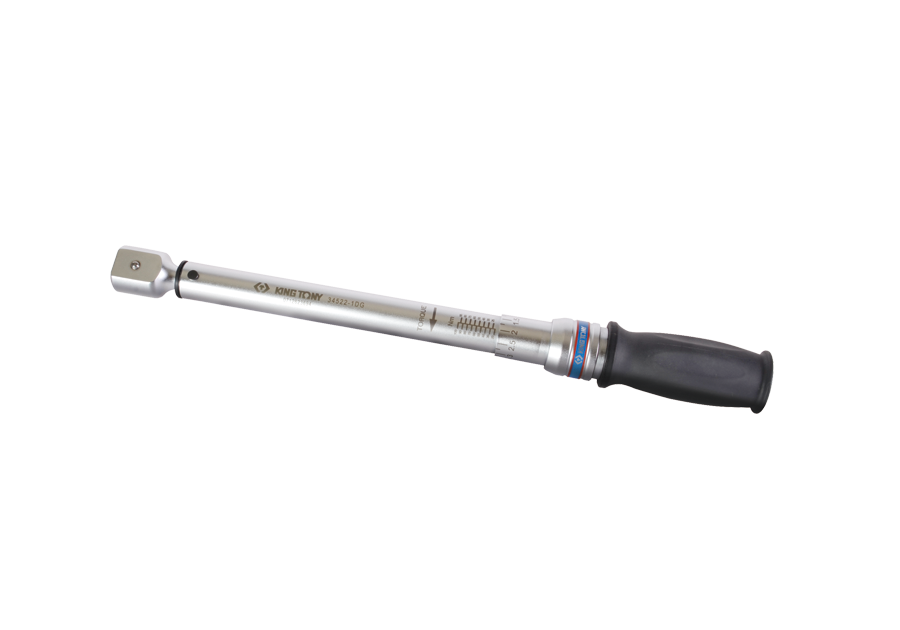

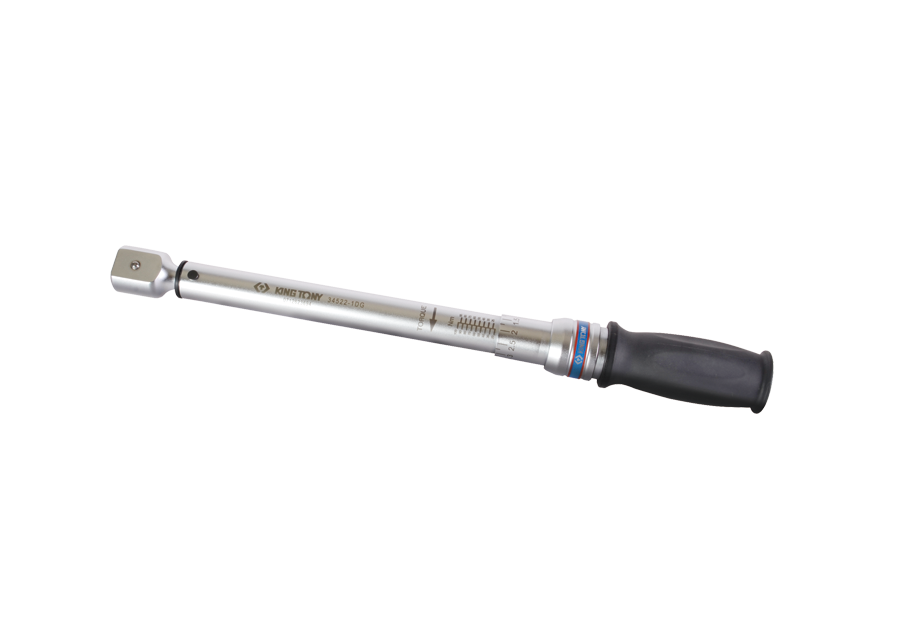

9x12 Heavy Duty Interchangeable Torque Wrench (Newton Meter)

34512-DG

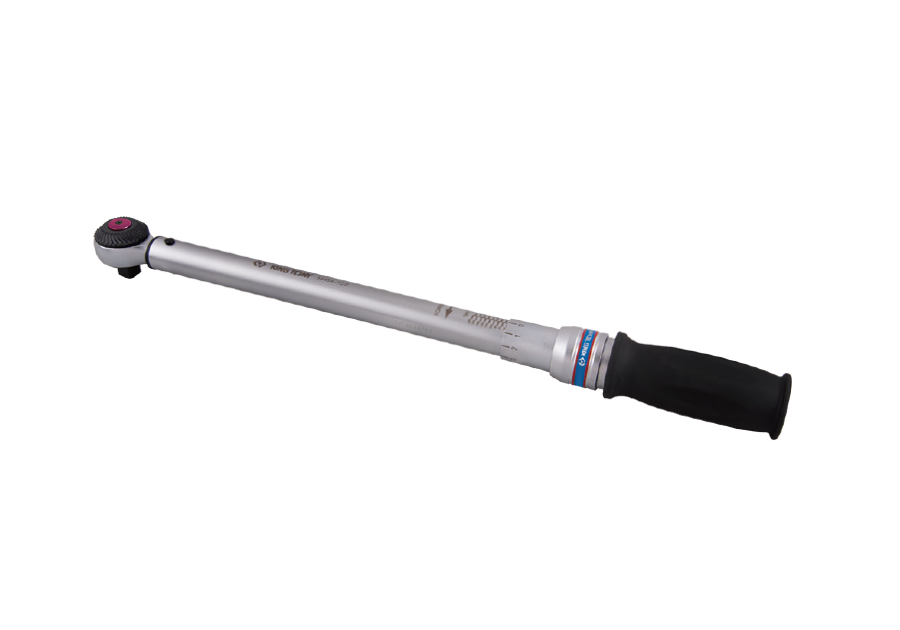

Heavy Duty Adjustable Torque Wrench (Newton Meter)

34462-DG

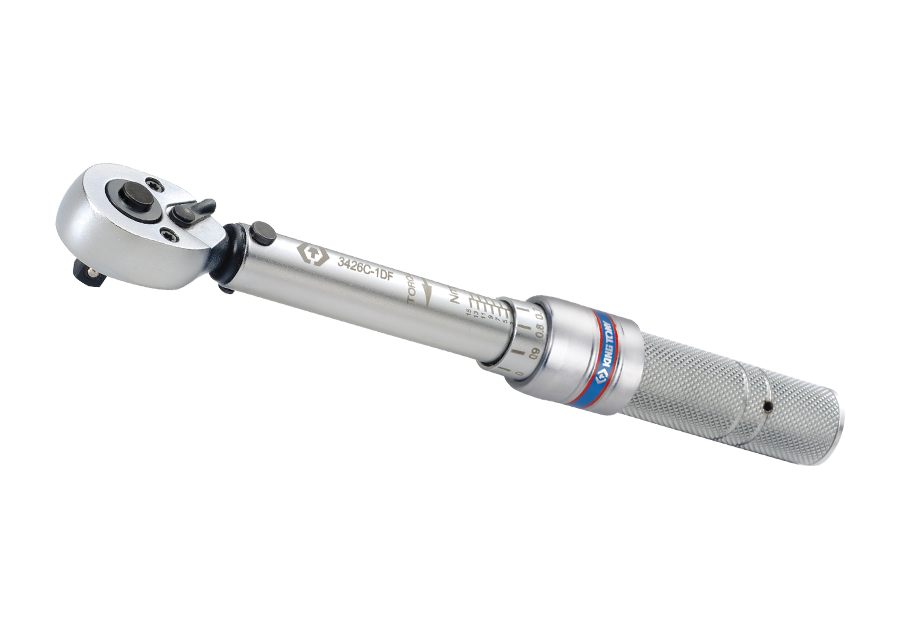

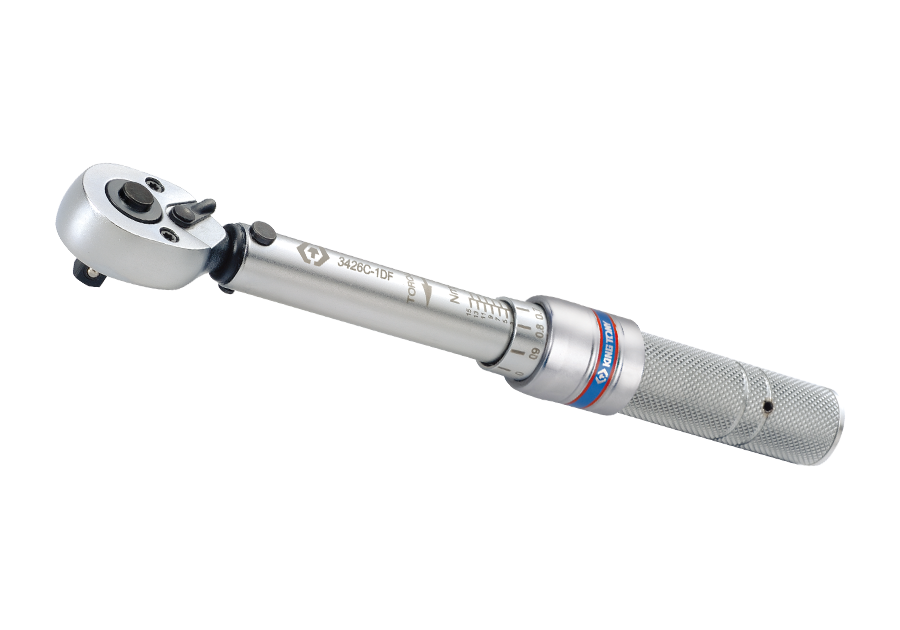

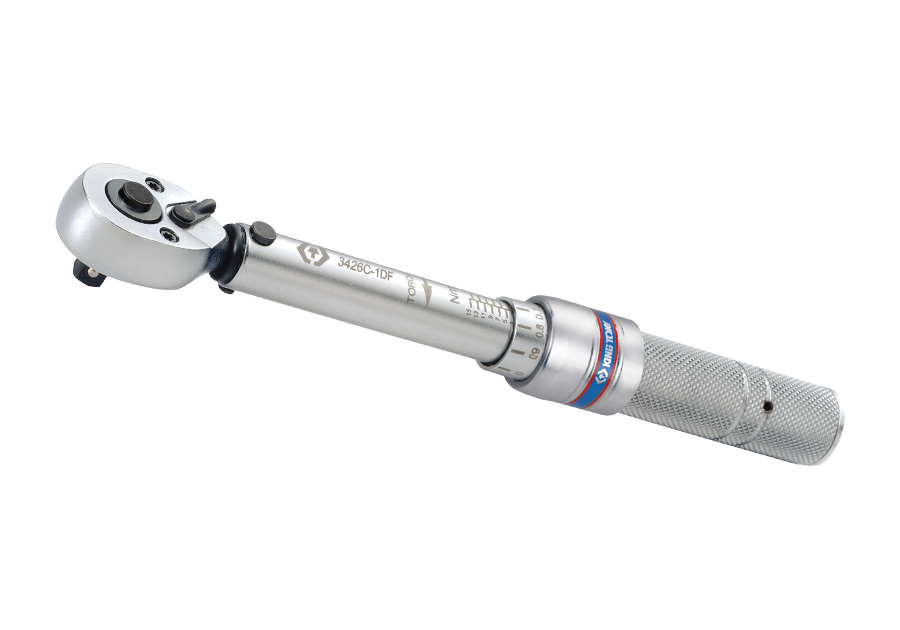

Mini-type Heavy Duty Torque Wrench (Newton Meter)

3426C-DF

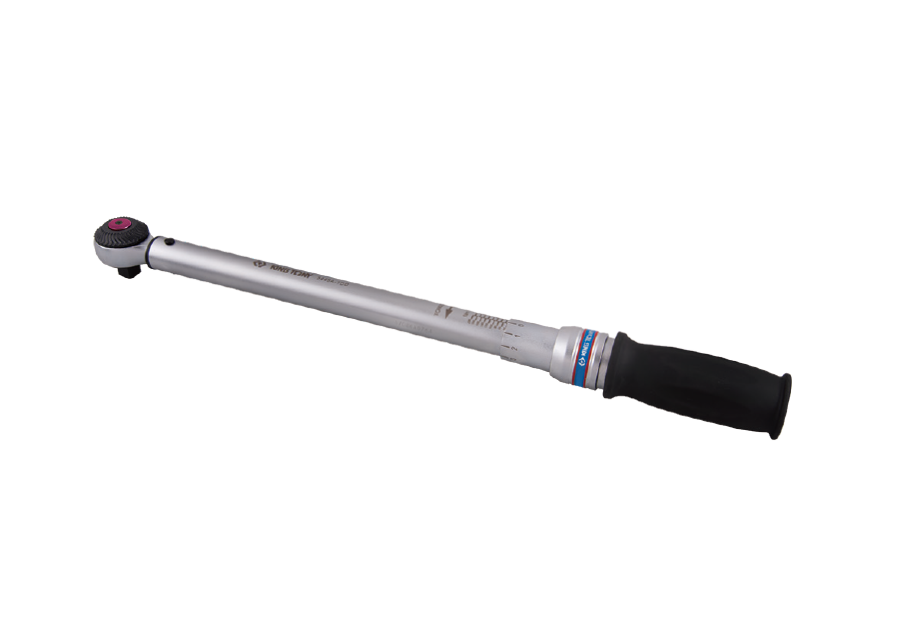

72PT Heavy Duty Adjustable Torque Wrench (Newton Meter)

3446A-DG

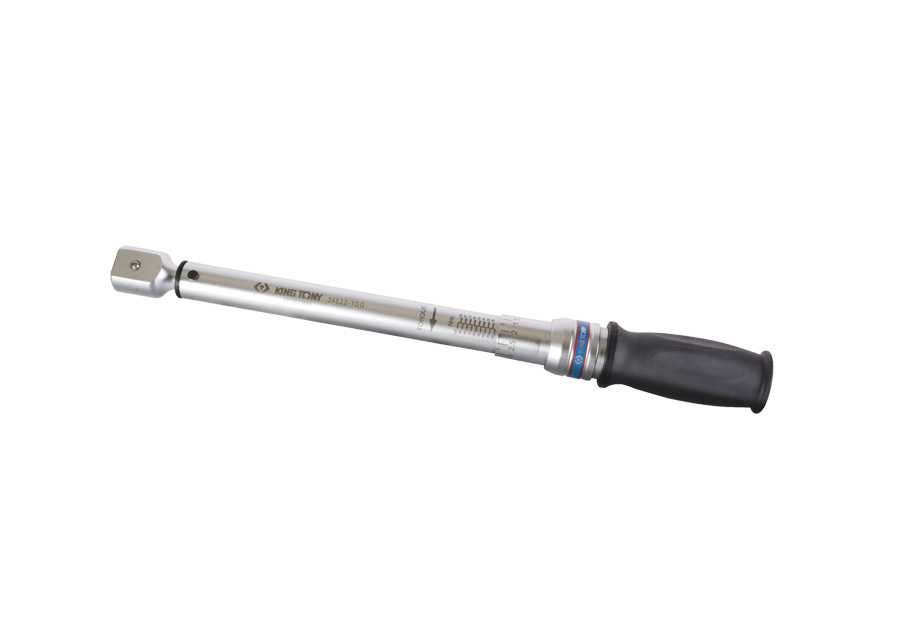

14x18 Heavy Duty Interchangeable Torque Wrench (Newton Meter)

34522-DG

Adjustable Torque Wrench (Newton Meter & Kilogram)

34423-AVery good tools<br />And i have many of them

- mazenalnajjar

- RE:Tony

- 2022-11-07 08:44:21

Do you have an exchangeable head time wrench for 1 Nm for small nuts and fittings. for example: 7, 8, 10 mm were a socket can't be used?

- Sascha

Hallow what is the best way to store the torque wrench

- Izak

- RE:Tony

- 2022-10-31 13:26:49