Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

How to Use a Wire Stripper?

Popularity : 963Wire stripping is a routine to electricians and engineers. The goal is to peel off the insulation of the wire and cable in order to connect or repair the electric circuit.

Same as all kinds of electrical engineering, that safety is the first priority. The wire stripper is invented and produced to increase the security.

Due to the inappropriate stripping may damage the wire and lead to security risks, the wire stripper, as a professional tool, allow users to strip the thin sheath with sharp knife, hence, the safety has increased and the accidental injuries can be reduced.

Wire Stripper Operating Instructions

-

What kind of cable are you stripping?

Assure the specification of the cable initially. The information mostly is printed on the sheath. It is also significant to ensure the wire is whether solid or stranded.

-

Is the tool you select suitable for the cable?

It is important that the specification of the cable should be corresponded to the stripping hole of the wire stripper.

If the stripping hole is bigger than the cable, then the sheath will not be cut through and stripping will also be difficult. On the contrary, the wire may be damaged and ruined if the stripping hole is smaller than the cable.

-

Is the cable fixed properly in the stripping hole?

Press the grips toward each other, then the sheath will be cut through by the wire stripper.

-

Remember to remove the insulation.

Use the chip remover to dislodge the sheath of the cable.

Wire Introduction

-

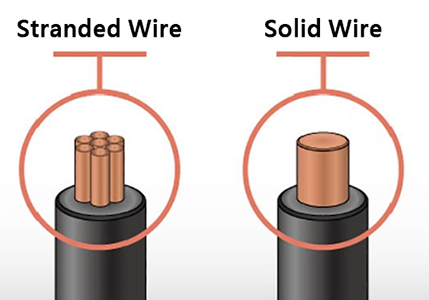

Stranded wire:

Composed by multiple twisted solid copper wires.

-

Solid wire:

Composed by single solid copper wire.

-

Standards:

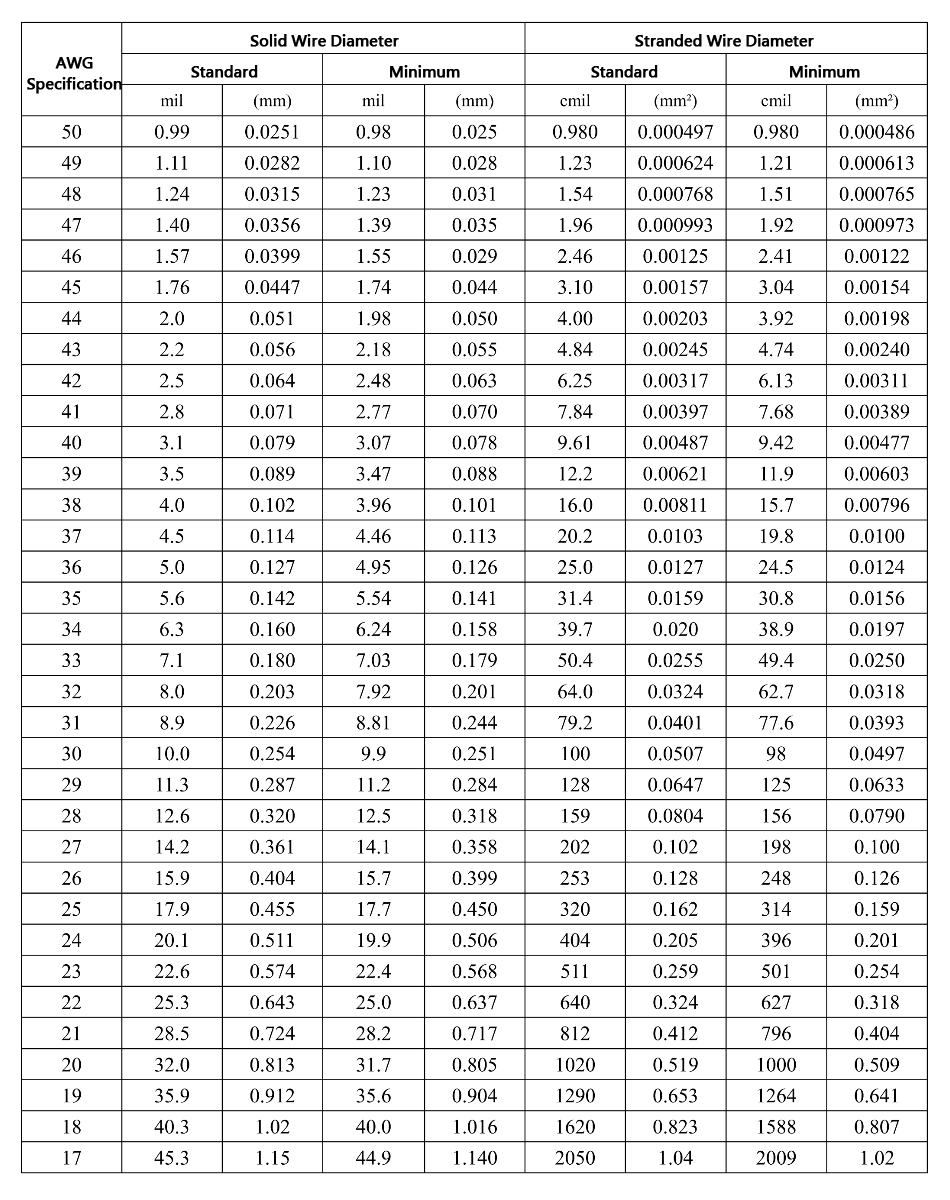

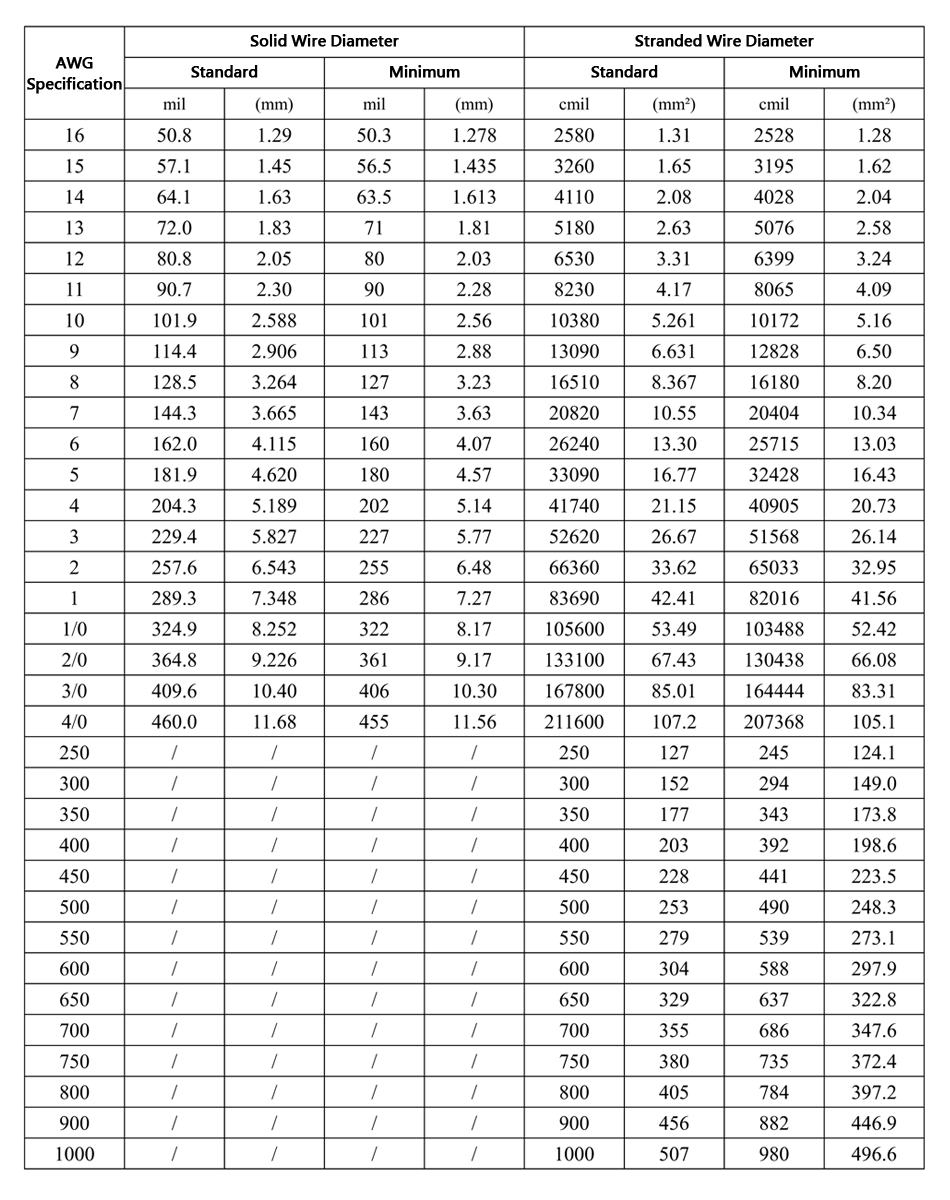

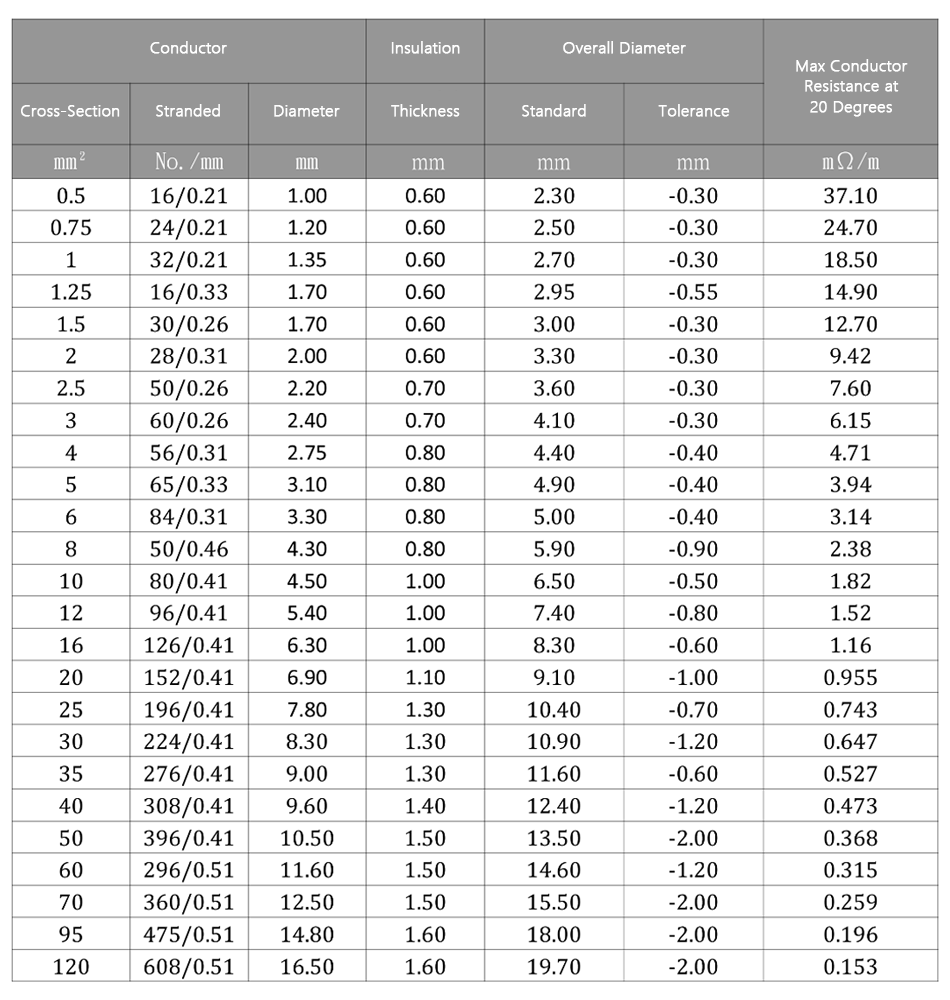

American Wire Gauge (AWG) / ISO Automotive Cables

Gauges of Specifications of Wires

American Wire Gauge -1

American Wire Gauge-2

ISO Automotive Cables