Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Basic Knowledge

Popularity : 25324The Positioning and Market Segmentations of the Hand Tools

| Market Segmentation | Positioning | Target Clientele |

|---|---|---|

| DIY Level | For general uses. |

|

| Professional Level | The basic level of professional hand tools. |

|

| Industrial Level | The upper level of professional level, and require higher quality of the products. |

|

| Aerospace Level | Higher than industrial level and have the strictest standard on the quality of the products. |

|

Differences between ‘Hexagonal’ and ‘Twelve Points’

-

Timings:

The hexagonal is traditional shape, yet the twelve points is a lot more popular despite it is invented later than the hexagonal.

-

Functions:

More angles means smaller degrees that each angle will be, therefore, lesser rotating degrees will be required when placing the tools into the screws.

-

Specifications:

The function and the specification of the twelve points and the hexagonal are exactly alike. The serrated interior can be inserted onto the head of the bolts or nuts tightly, moreover, it is also named ‘Ring’ due to the similar appearance between a ring and the twelve points end wrench.

The red frame in graph 1 represents the hexagonal and the black frame stands for the twelve points. After overlapping the two of them, the outcome depicts that one more angle can be utilized in each surface of the hexagonal.

Graph 1

What is the Function of the Wrench’s Angle?

The selection of the angle of the required wrenches is based on the working environments or the depth of the screws that are inserted on the machines.

The issue of inconvenience is often occurred when using wrenches due to the working environments, spaces or the position of the machines that need to be repaired. Hence, to increase the accessibility and convenience, wrenches are designed with multiple angles that allow users to accomplish diversity jobs.

Straight wrenches are suitable for disassembling screws in plane surface.

Choose the wrenches according to the depth of the position of the screws.

Applications of Different Amount of Teeth of Ratchets

KING TONY provides ratchets with five types of teeth.

The most significant difference between diverse teeth is the rotating degrees.

The degree of circumference is 360 degrees. More the amount of the angle is, less the degree of each angle will be. Graph 2 and graph 3 illustrate that the degree of each angle will be 5 and 15 degrees respectively when the ratchets are 72 teeth and 24 teeth.

Graph 2

Graph 3

Graph 4

Merit:

The direction need to be rotated in order to conform to the angle of the hexagonal screws or sockets while working. The smaller the angle of the tooth is, the lesser that the tools need to be rotated. Take vehicle mechanics as example, when repairing vehicles in a narrow space, the problem of inconvenience of rotating in big angle will occurred due to the cramped working space.

The advantage of low amount of teeth:

As the graph 4 demonstrates, the gear and the left and right components are conflicted to each other, which implies that every tooth can own bigger surface when the number of teeth is lesser, and the structure will be stronger and more solid.

Types of Bits and Bit Sockets

Can be divided into several types according to the head of the tools.

Quick Release (QR.) Button

Separated, according to the feature, into ‘QR. Type’ and ‘ Non-QR. Type’.

Apart from the direction button on the main body that can control the rotating direction between clockwise and counterclockwise, a round button, which is the QR. button, can control the assembly and disassembly of the sockets.

-

Press the QR. button then the steel ball will submerge in order to reduce the resistance of installing the socket.

-

The socket cannot be disassembled without the QR. button being pressed, which can prevent the accidents that might be caused by slipping off.

Applying the socket is to increase the friction between the socket and all kinds of adapters, such as extension bars or ratchets. Ball retaining grooves are designed inside the square hole in order to avoid the circumstance of shaking when the socket is installed.

The ball retaining grooves can be matched with the steel ball on the adapters, and the QR. button is exactly designed for these grooves.

The QR. button ought to be pressed in both situation of Installing and disassembling the socket. The safety design can reduce accidents from happening when working in height.

Link to KING TONY E-Learning ”Know the Hand Socket and Impact Socket” to know more~

Simple Classification and Introduction of Tools

Separated, following the power source of driving force, into two types, which are human force and machinery force.

| Driving force | Product Categories | Differences | ||

|---|---|---|---|---|

| Torque | Speed | Price | ||

| Human force | Hand tools | Weak | Slow | Cheap |

| Machinery force | Pneumatic tools | Strong | Quick | A bit steep |

| Electrical tools | Middle | Quick | Expensive | |

| Hydraulic tools | Extra strong | Slow | Expensive | |

Usage of Hand Tools

Usage of all kinds of wrenches.

| Types | Usage | Environment | |

|---|---|---|---|

| Open End Wrench - 1900 Box End Wrench - 19C0 Combination Wrench - 1062 |

For tightening or loosening outer hex screws or nuts that are utilized on fixing and holding. Some wrenches are provided with 45 degrees and 75 degrees in order to reach the screws or nuts in different depths. | Normally used in factories, car repairing and locomotive industries. | |

| L Type Hex Key - 1130MR | For tightening or loosening inner hex screws. | Normally used in factories, car repairing and locomotives industries. | |

| Adjustable Wrench - 3611 | For tightening or loosening outer hex screws or nuts that are utilized on fixing and holding. Noticeably, the size of the using end can be adjusted. | Normally used in factories, car repairing and locomotive industries. | |

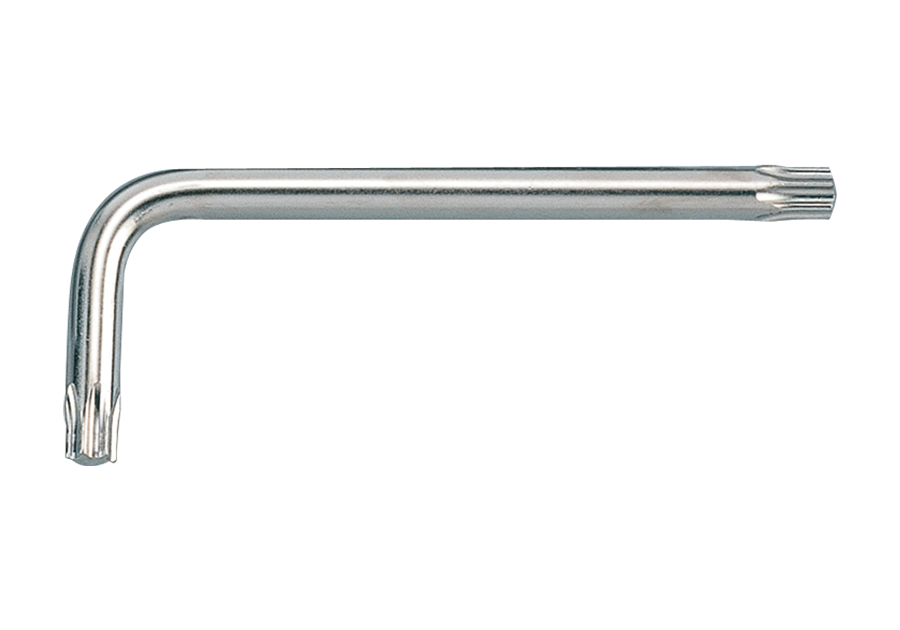

| Star L - 1143R | For tightening or loosening inner hex screws. | Normally used in factories, car repairing and locomotive industries. | |

| Angled Socket Wrench - 1081 | For tightening or loosening screws or nuts that are utilized on fixing and holding in architecture industries. | Normally used in factories, car repairing and agricultural machines. | |

| Speed Wrench - 3730M | For tightening or loosening screws or nuts that are utilized on fixing and holding. | Normally used in factories, car repairing and locomotive industries. | |

| Flare Nut Wrench - 1930 | For tightening or loosening screws or nuts that are utilized on fixing and holding the oil pipes. | Normally used in factories, car repairing and locomotive industries. | |

Link to KING TONY E-Learning ”Wrench” to know more~

Screwdrivers

Usage of all kinds of Screwdrivers.

| Types | Usage | Environment | |

|---|---|---|---|

| General screwdrivers - 1422 1421 |

For assembling and disassembling screws. | Normally used in regular industries and machine repairing. | |

| Electrician screwdrivers - 1472 1471 |

For assembling and disassembling screws in places with electricity or places that are easy to receive an electric shock. | Normally used in places with electricity or places that are easy to receive an electric shock. | |

Link to KING TONY E-Learning ”Screwdrivers and Bits” to know more~

Recommended Products

Reversible Speed Wrench

3732S

75° Offset Ring Wrench

1970

6 Point Flare Nut Wrench

1930

Flexible Speed Wrench

3730M

Speed Wrench

3731M

Double End Speed Wrench

3736M

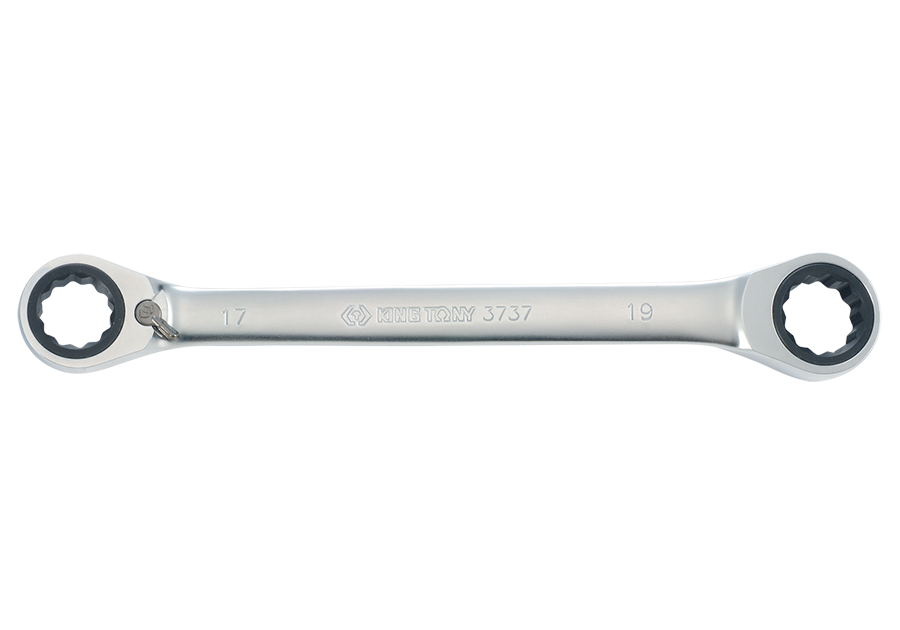

Double End Speed Wrench

3737M

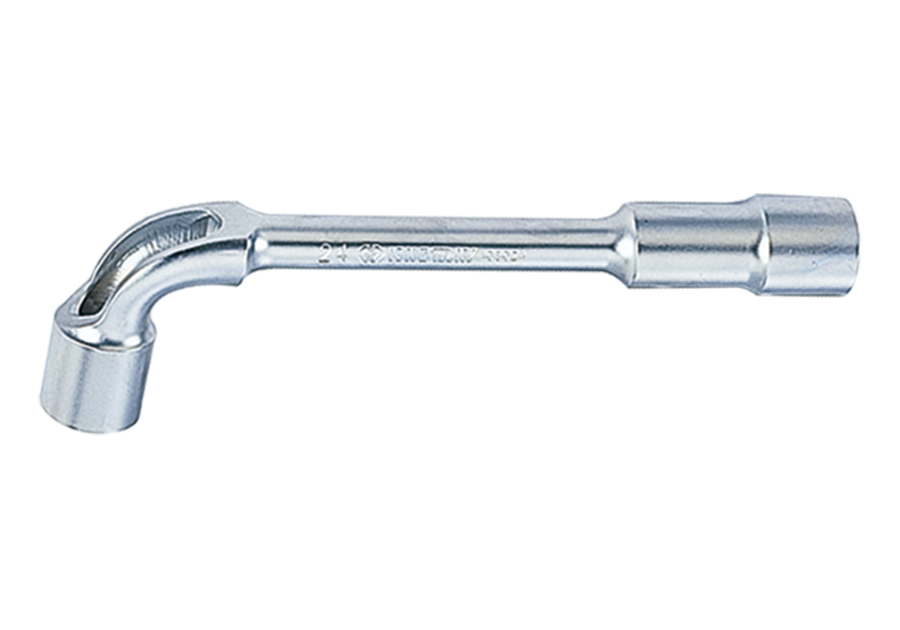

Angled Socket Wrench 6PT x 6PT

1081

Adjustable Wrench

3611

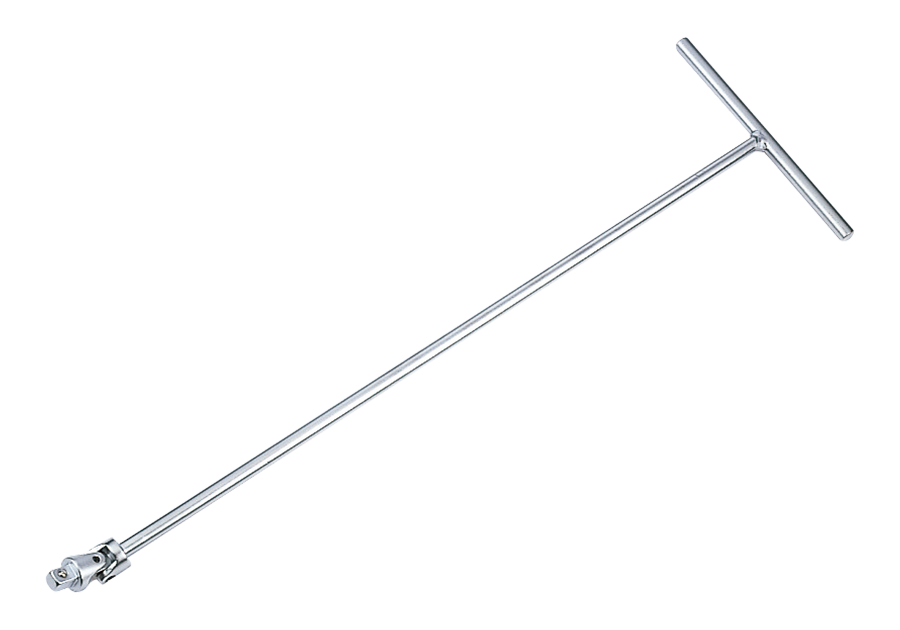

1/2" DR. T-shaped Universal Joint Driver

4795

Combination Wrench

1060

Open End Wrench

1900

1/2" DR. 12 Point Metric Deep Socket

4230M

1/2" DR. 6 Point Metric Deep Socket

4235M

1/2" DR. Star Socket

4375M

1/2" DR. Universal Joint

4791R

Ball Hex Key (Long arm)

1130MR

Ball Hex Key (Long arm)

1130SR

Ball Hex Key (Extra long arm)

1120MR